Moving on the everyone's favorite, the <dun...duuuun> CLAW.

Hope you are paying attention Ray, 'cause here come the sensors.

There are a bunch of things to keep tabs on with this crazy thing and some relief comes in the form of 'position reached' signals available from the servo drives. All positioning of the arm and the carousel will rely on those signal from he drives and will serve as 'sensors' for that part of the sequence.

Things that are monitored in the following photos are:

1) is the CLAW open?

2) is the CLAW closed? (same sensor, but a different event)

3) is the interlock in place?

4) is the interlock retracted? (same deal)

For continuity, I'll mention these as well although they will be in the next post along with the new spindle lock

5) is the spindle lock engaged?

6) is the spindle lock released? (seems redundant, but some events need two separate sensors to monitor each state)

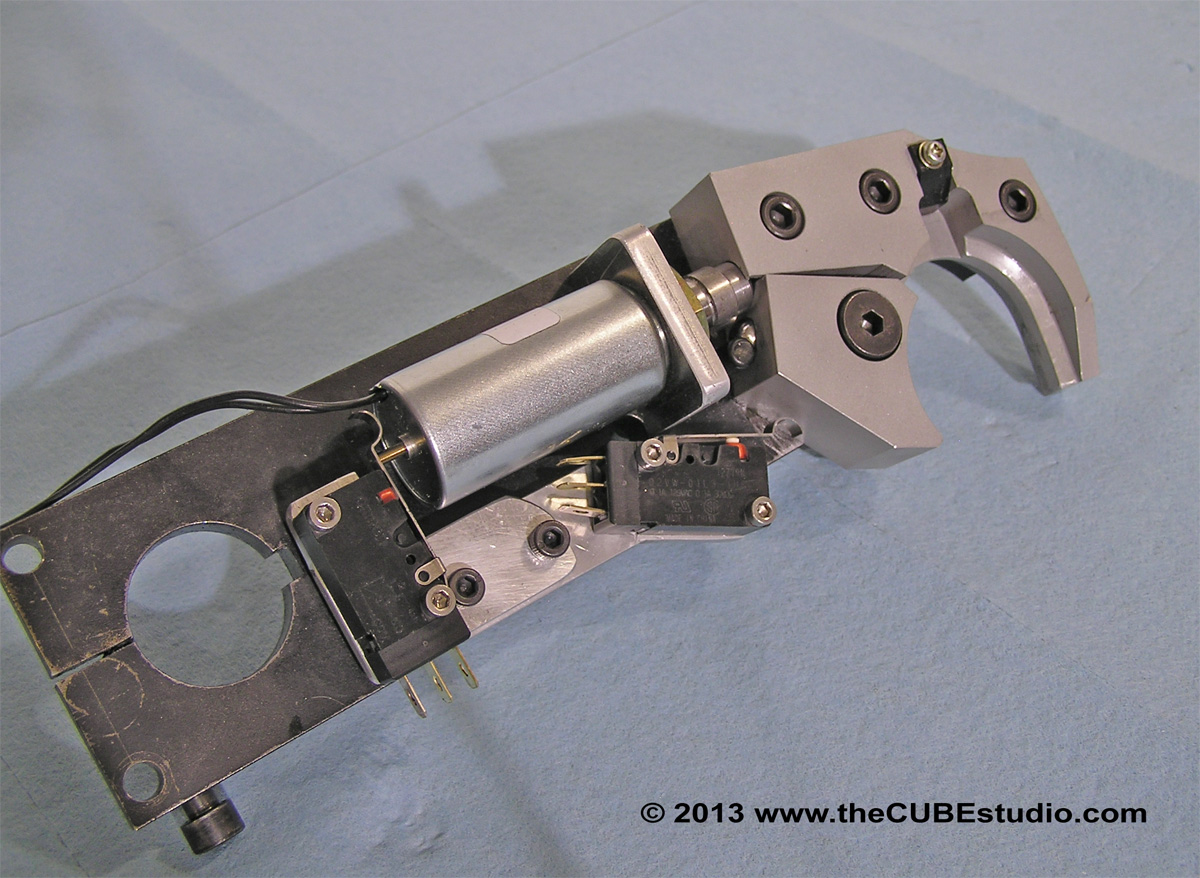

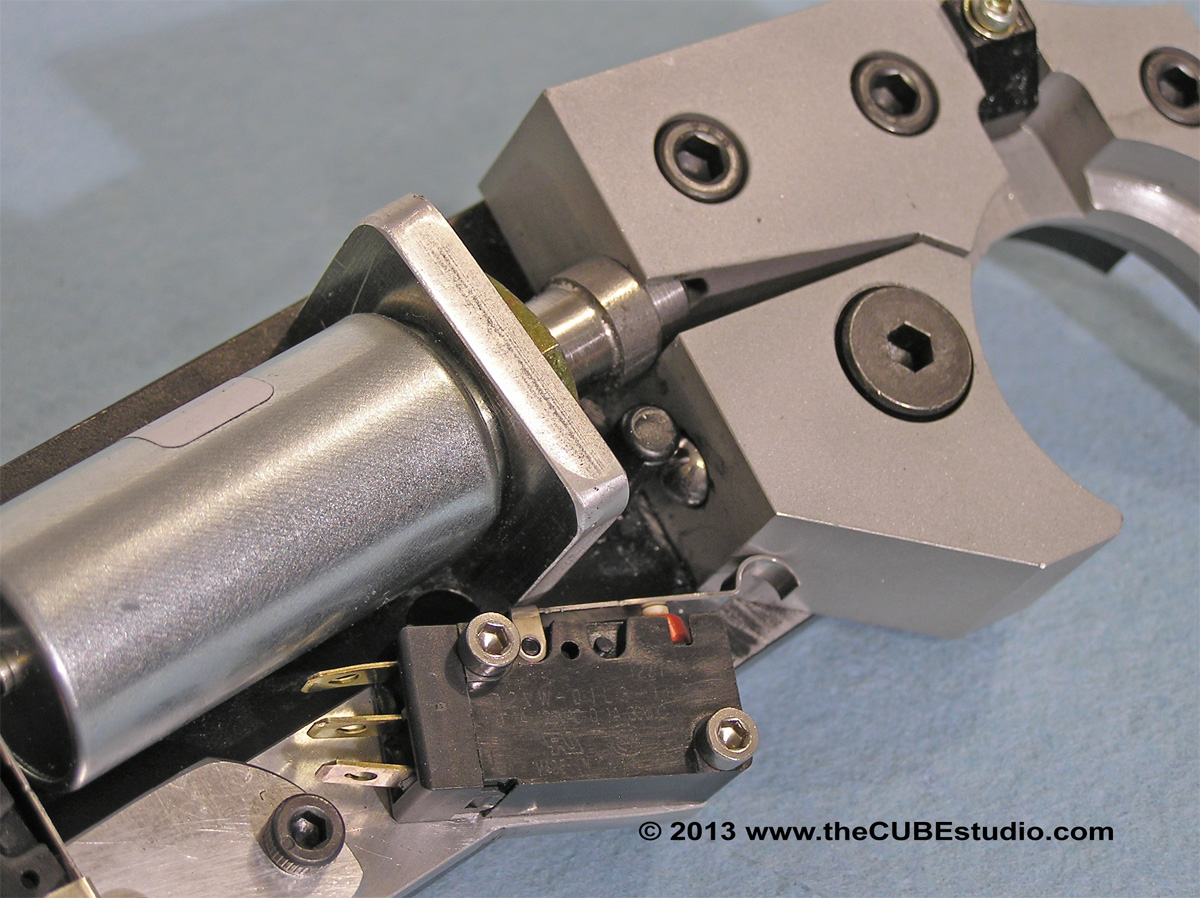

The first photo is the overview. The second is self explanatory and shows the switch that 'watches' the claw closure.

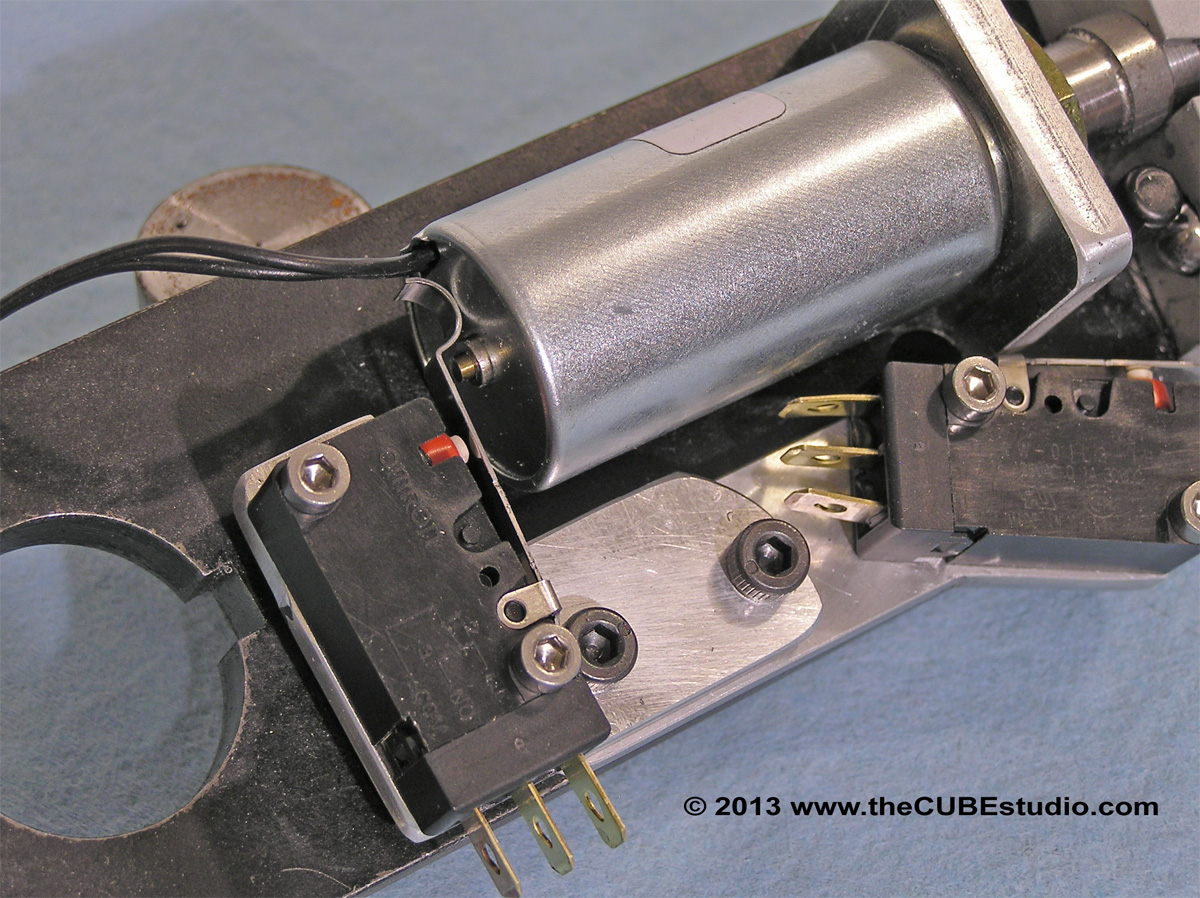

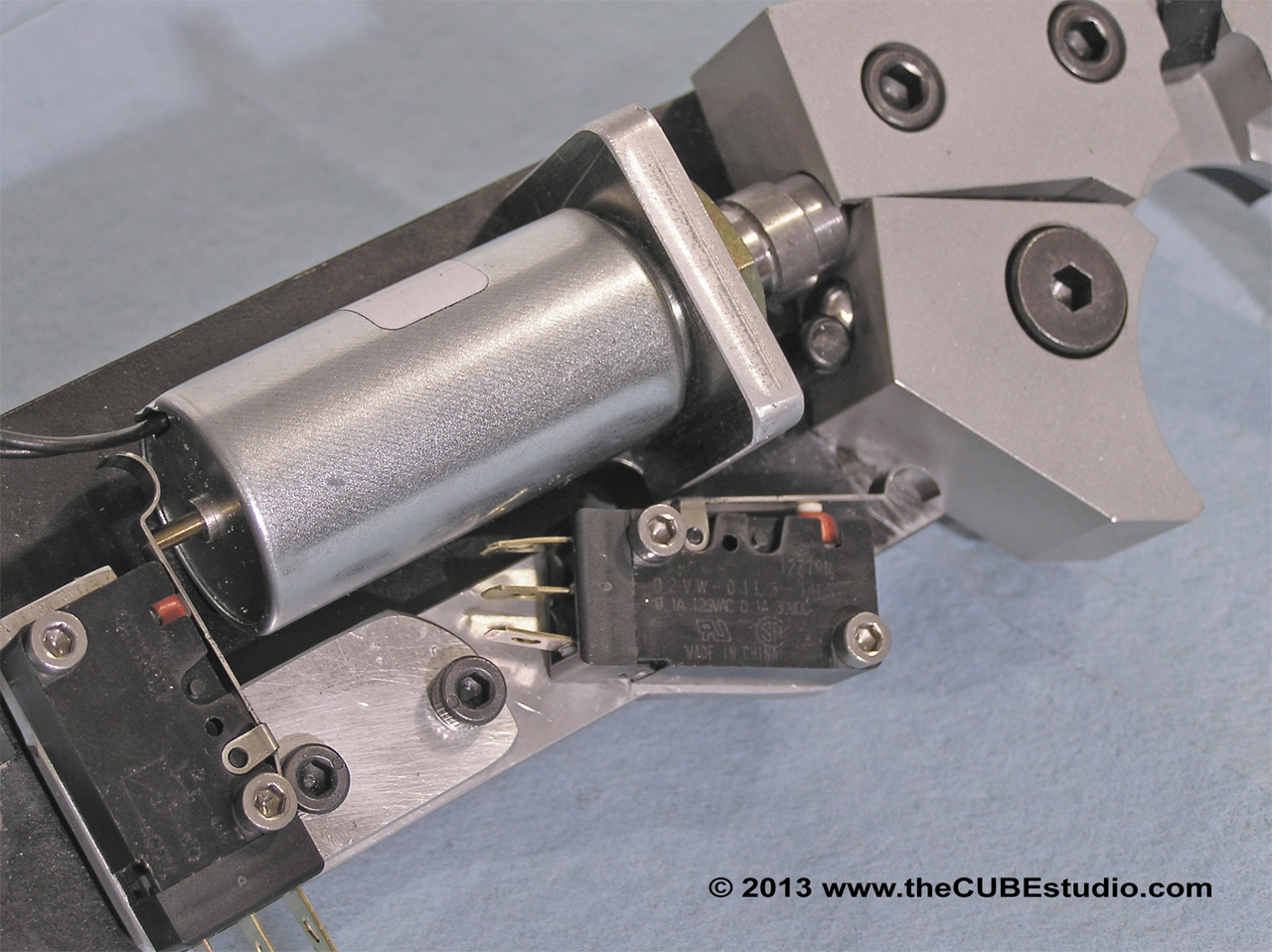

The last two show the switch that looks at the solenoid. This was a little more complicated in that I had to make the specialty shaped plunger from scratch and add a small rod that extends outside the solenoid case and activates the switch. These particular solenoids do not come with a spring extender so I have to add that internally to both this solenoid and the drawbar interlock solenoid.

The solenoids and the switches are sealed, but I think that I shall still put a cover over the whole works on the arm to keep junk from interfering with the workings. There are a million nooks and crannies that all need to stay relatively clean.