I am currently working on the sensors and control software. The last sensors are for the arm up/down and I could find no way to get those on the shaft that satisfied me. It is more complicated than it looks because the shaft will be covered by a rubber corrugated bellows below the gearbox and by either the same bellows or just a cover tube between the air cyl and the gearbox . . and of course the whole shaft rotates. Also I'm not crazy about the air cyl being mounted separately from the gearbox. So I had to go on hold with that until I get a new cylinder with position sensors on the cylinder itself. I have the cylinder on the way and I plan to mount it on a tube supported by the gearbox.

My secondary task was working on the software, but I am building on top of the InTurn™ motor controller and in a moment of apparent masochism, I reasoned that this was a good time to do a major upgrade to the controller and launched into that. Among other things, I changed the interface from serial modbus to plug-in modbus . . which took more than a few minutes.

THEN, after a few brewskies, it seemed sensible to move my own development box to TCP modbus. After all the setup on MACH's side is similar to the plug-in serial, right? Well, in my setup, the "PLC" runs the modbus slave, so moving from 'serial anything' to TCP was a rewrite of a significant part of the code.

Those are my excuses. If I come up with better ones, I shall post them separately. The work is completed and working now, but apparently too late as it seems the tortoise has crossed the line.

So, Ray, if you are declaring your 'first' ATC completed including all sensors and controls, then all I can say is CONGRATULATIONS and where do I send the beer

I accept your challenge to finish my first before you finish your second. However, I counter challenge you to see who is the first to have a completed and sold version operating in the field. I believe I have the drop on you there.

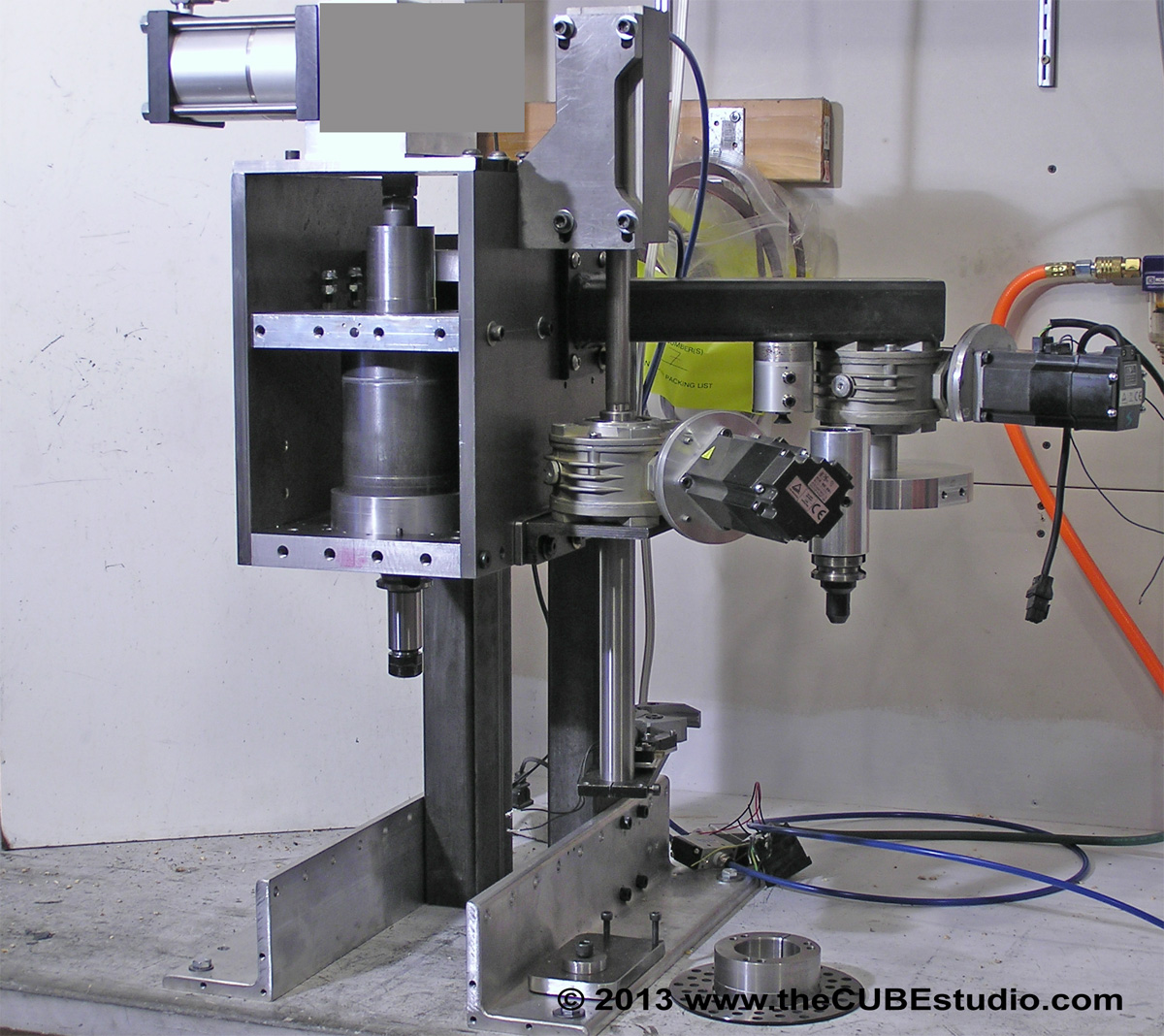

Anyway, at the time you took the checkered flag, I was on this lap: Note that the carousel gearbox can be rotated in 90 degree increments and the drive motor will be tucked in at final assembly. It is flying out there now to make the thing easier to work on and observe the actions.