Will this thing make coffee in the morning as well(;-).

No, but there is a Margarita adapter for the ATC.

Have you considered just adding the turret mechanism to the spindle housing and just index the spindle then relock the turret solid each tool change. You could add the index slots to the spindle housing then use the Power draw bar to lift the turret off the slots then use the spindle motor to rotate the turret then release the power draw bar to engage the slots again to lock it down.

When you say spindle 'housing' I think you mean the spindle itself? If so, then yes, attaching to the spindle nose may be the way to go. I really wanted to avoid having the spindle stick down past the bottom surface of the head, but that may be what I'll need to do.

That way you do not need a huge servo OR brake mechanism JUST to hold the turret in position

You have a knack for making suggestions right AFTER I have finished building something . .

However, notching would not be adequate for the spindle because fine adjustments are needed for the tools. Something that is extremely cool is to cut up to a shoulder in one direction and then just rotate the tool and cut up to another shoulder in the opposite direction. Saves a tool change! But the rotation is not exactly 180 degrees, hence notching would be an impediment. Besides that, I have already added a substantial rotor (see photos) and will use one of the 4th axis calipers with it. You can't move the 4th axis spindle or the mill spindle when locked, trust me on this.

When NOT in lathe mode the spindle then uses a standard BT30/40 tool holder. IF you are going to move up to 40 you might want to consider Cat40 as they are more common in the used market than BTs.

The jury is still out on this question. I'm working on other stuff right now so I will revisit this question later and consider all suggestions. I have completed the PDB design. Quite unique I will say . . extremely compact. It mounts on the head, so I will need to mock up a head to do any testing. Hood expressed that he liked that on his mill a lot of stuff follows the head around, I have that as a design goal. We shall see.

Incidentally, 'your' bearing retainer has come in handy as a leg up on incorporating an oil seal. SKF has some contact seals good for about 7k RPM, so I am going to use that instead of the labyrinth with the current bearing because I do quite a lot of grinding. I have added a positive pressure purge to the housing already, but that can just be plugged. The labyrinth and purge is still necessary for high RPM with the precision bearings though, so it is good to have also.

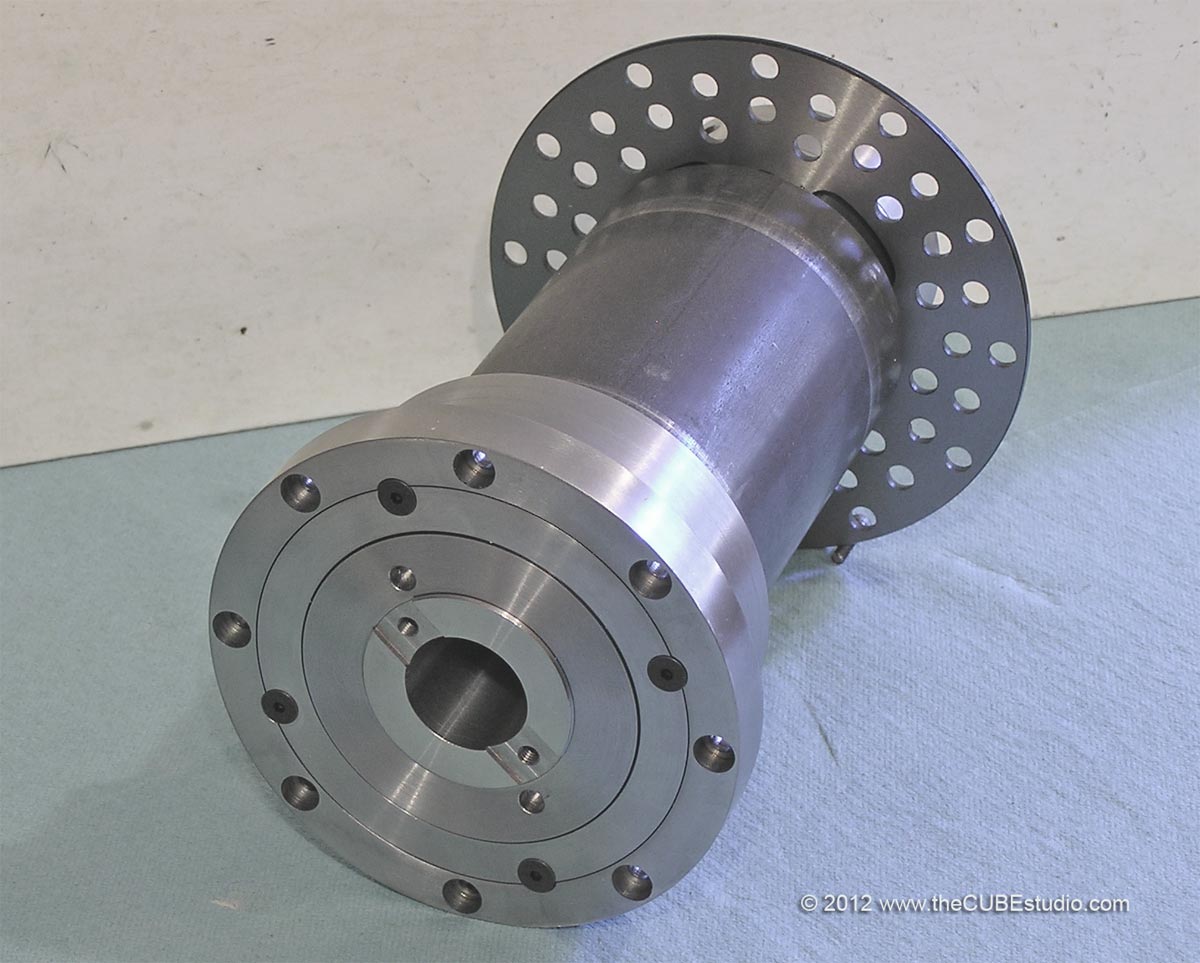

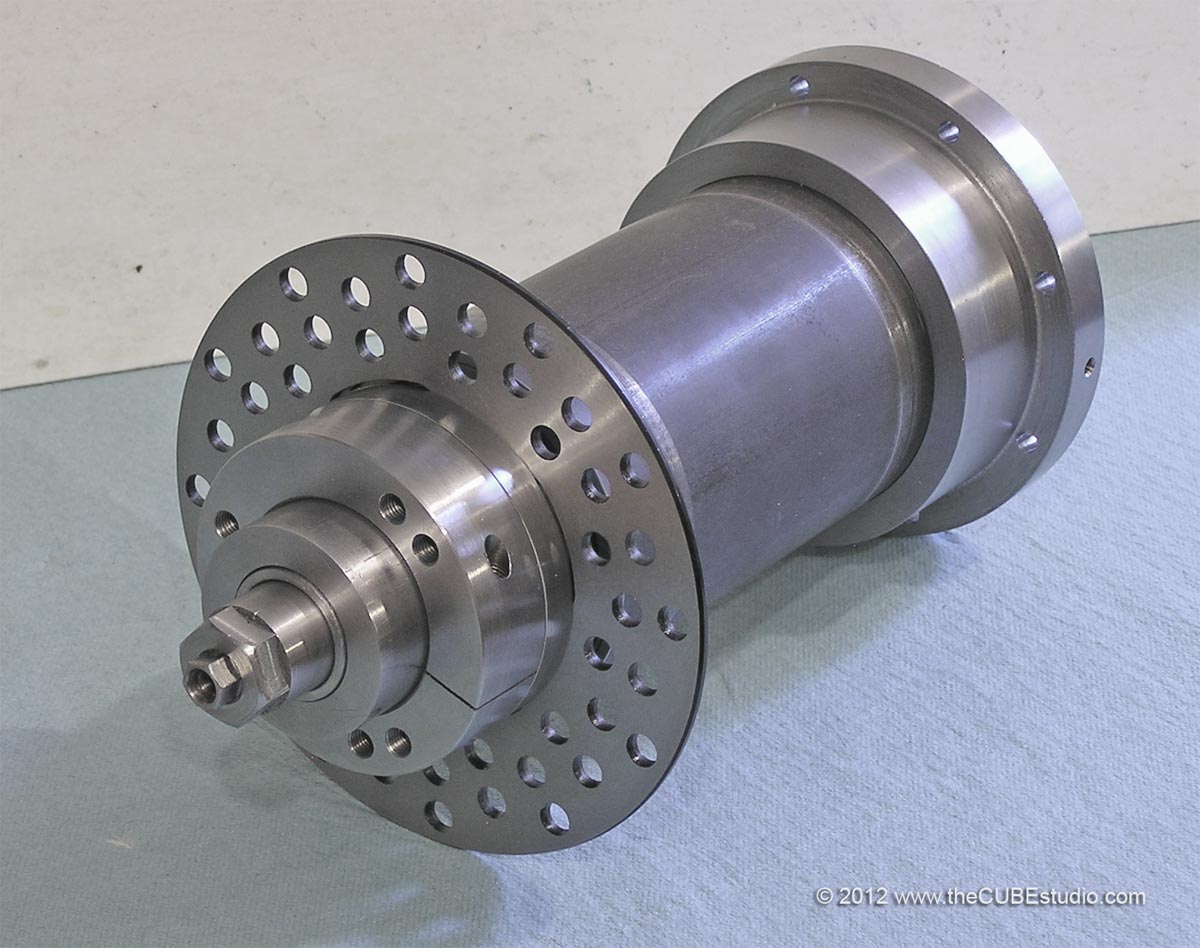

Spindle lock rotor: