A sneak peek into next job, one more for colin, oversize head and shank for a LARGE amethyst.

This is the stone, usb jack for proportion

The shank is not worth going into detail on, just a pic, simple flip cut

SOme pathing imagery

Half the job to be cut

Roughing the rotary pass

Finishing the Rotary Pass

Top Down Roughing

Top Down Finishing

Melt some tube!

Hook some oversize wax into the lathe

Surface it

Load into Mill

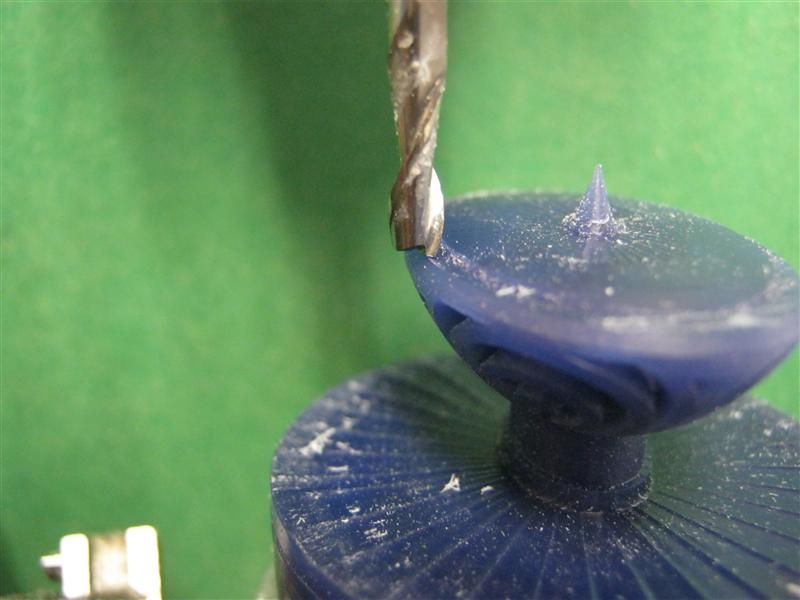

Roughing

[video]http://www.youtube.com/watch?v=XJYVsiIG8h4[/video]

Roughing COmplete

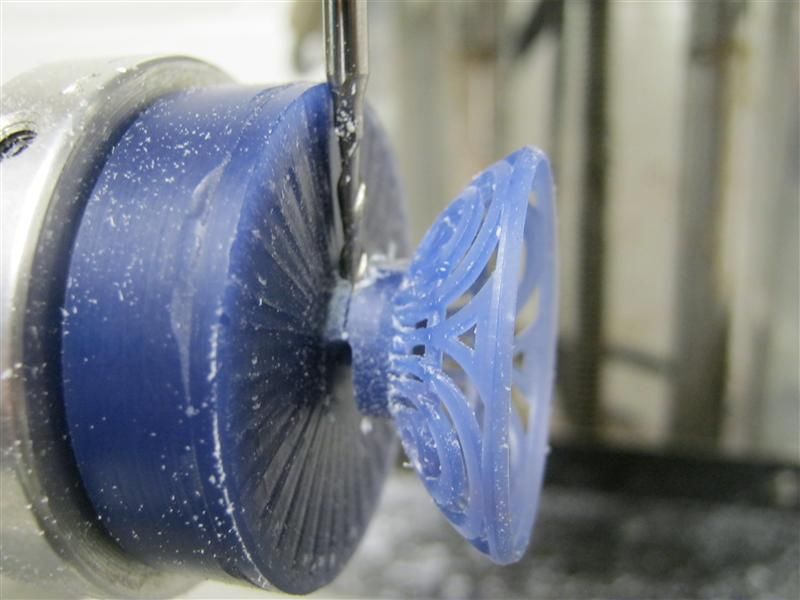

Finishing Starts

Finishing Finished.. 5 hours later....

Rotate Fixture upwards 90'

Zero out X and Y

Zero out Z

Top roughing

ROughing done!

Change cutter and rezero fo final pass

[video]http://www.youtube.com/watch?v=ZrQqIWpYYsk[/video]

Finishing pass done!

Cutoff Profile operation

and she is done.. phewwwwwww