I have been planning this for a long time. I just have not had the time or money to start on the project. I have changed my mind on the design many times. I think I finally have it down the way I want. for the most part it is going to look like any other C-frame style brakes with a few improvements.

Specs:

48" wide

58 tons

6" inches of ram travel

2 axis servo backgage

Mach 3 control with a Dynomotion motion controller for the control of the +-10V analog Parker Proportional valve.

5hp, 2.5GPM pump.

I will be building the entire thing including the cylinders. ( That's what I do for a living.)

I am going to start of with building the 2 cylinders first. The cylinder are 5" bore, 3" rod, and 6" stroke.

Pile of Parts

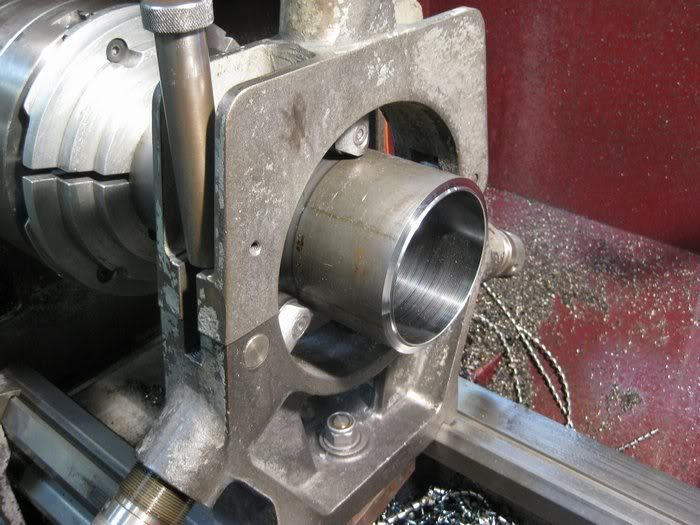

Rough machining of the base heads. I will finish machine them after I weld them to the barrel.

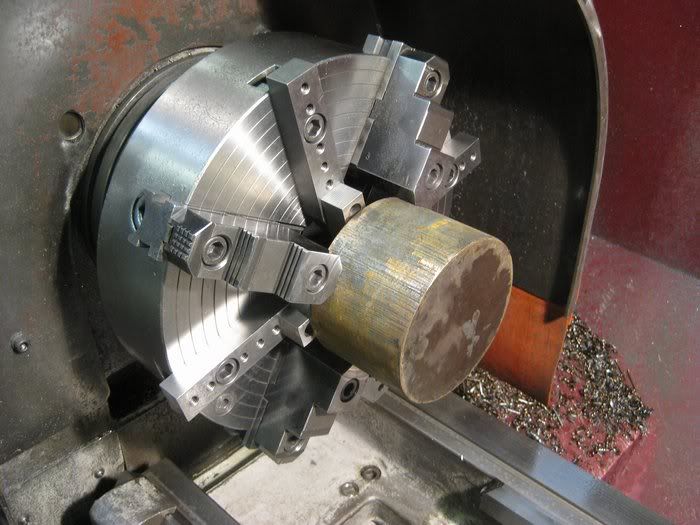

Pistons are next.

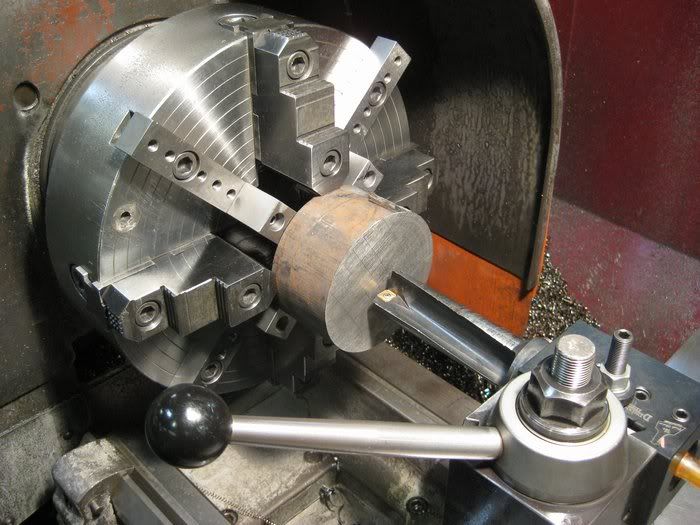

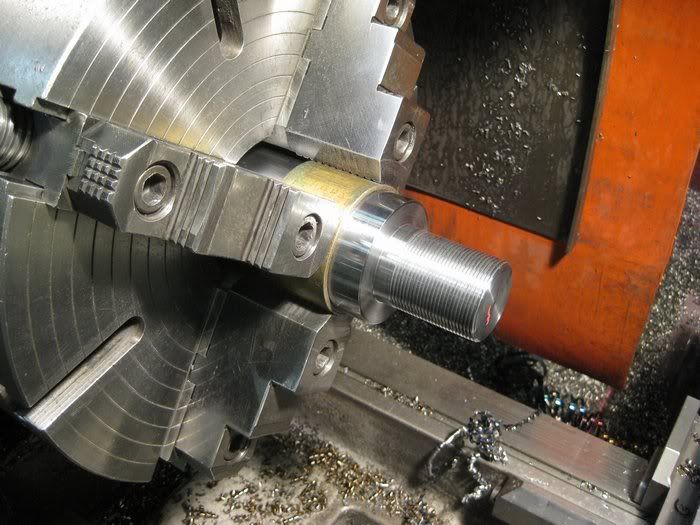

Checking the threads with a Go gauge.

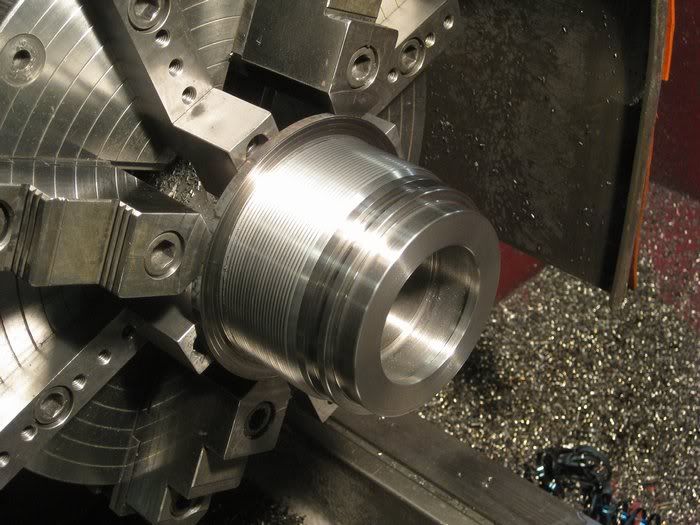

Rod heads next.

Piston rods next

Weld prep on the barrel.