Hello all,

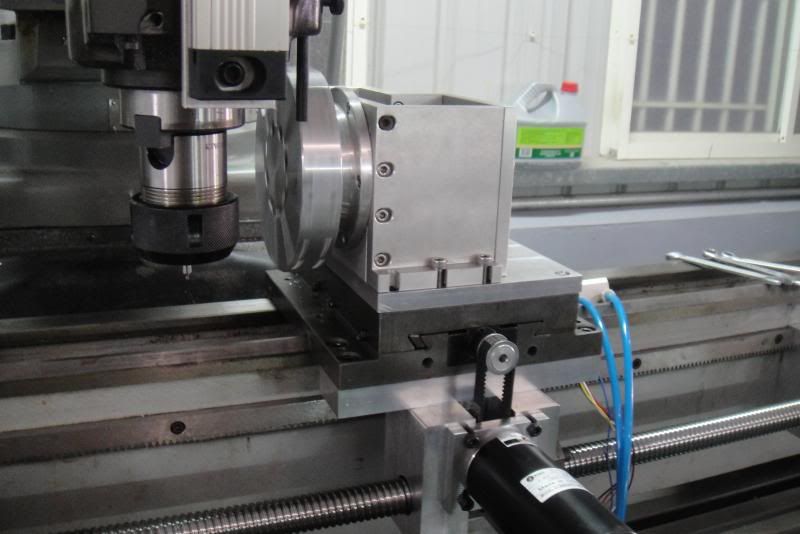

Previously I completed a cnc conversion on BVB25L lathe and now I'm adding a 8 station tool turret to this cnc lathe:

I know I need a macro code for this, I did a search on Machsupport forum, found some code but not sure if that's the suitable one, here's the link:

http://www.machsupport.com/forum/index.php/topic,15569.0.htmlcan I use the code below for my tool turret?

'Macro Tool Changer

Sub Main()

Dim Tool As Integer

Dim OldTool As Integer

Dim NewTool As Integer

Dim MaxToolNum As Integer

NewTool = 10

MaxToolNum = 8 'Maximum positions on Automatic Tool Changer

Tool = GetSelectedTool() 'Get the toolnumber from the command e.g T0101 M6 Tool number 1

OldTool = GetCurrentTool() 'Get current tool number

If Tool > MaxtoolNum Then GoTo 6

If TOOL = OldTool Then GoTo 7

ActivateSignal(Output3) 'Turn on output signal to turn off spindle and turn on the atc

sleep(10)

ActivateSignal(Output4) 'Turn atc forward

sleep (3000) 'Needed to start atc otherwise it plays up

While NewTool <> Tool

' CheckPins

If IsActive(Input3) And Not IsActive(Input2) And Not IsActive(Input1) Then

NewTool = 1

GoTo 5 'StopTool

End If

If Not IsActive(Input3) And Not IsActive(Input2) And Not IsActive(Input1) Then

NewTool = 8

GoTo 5 'StopTool

End If

If Not IsActive(Input3) And Not IsActive(Input2) And IsActive(Input1) Then

NewTool = 4

GoTo 5 'StopTool

End If

If IsActive(Input3) And Not IsActive(Input2) And IsActive(Input1)Then

NewTool = 5

GoTo 5 'StopTool

End If

If IsActive(Input3) And IsActive(Input2) And IsActive(Input1) Then

NewTool = 7

GoTo 5 'StopTool

End If

If Not IsActive(Input3) And IsActive(Input2) And IsActive(Input1)Then

NewTool = 6

GoTo 5 'StopTool

End If

If Not IsActive(Input3) And IsActive(Input2) And Not IsActive(Input1) Then

NewTool = 2

GoTo 5 'StopTool

End If

If IsActive(Input3) And IsActive(Input2) And Not IsActive(Input1) Then

NewTool = 3

GoTo 5 'StopTool

End If

Wend

5:

' Stoptool

DeActivateSignal(Output4) 'StopATC

sleep(10)

ActivateSignal(Output5) 'Run ATC in reverse

Sleep (3000) 'Wait 3 seconds to allow the toolpost to lock in

DeActivateSignal(Output5) 'Stop running ATC in reverse

Sleep (1000)

SetCurrentTool(NewTool)

DeActivateSignal(Output3) 'Turn off output to turn spindle back on

sleep(10)

GoTo 7

6:

MsgBox ("Tool out of RANGE")

Goto 7

7:

End Sub

Thanks,