Update on the swapaxis question: the third of my little PCB projects is now complete and tested . . .

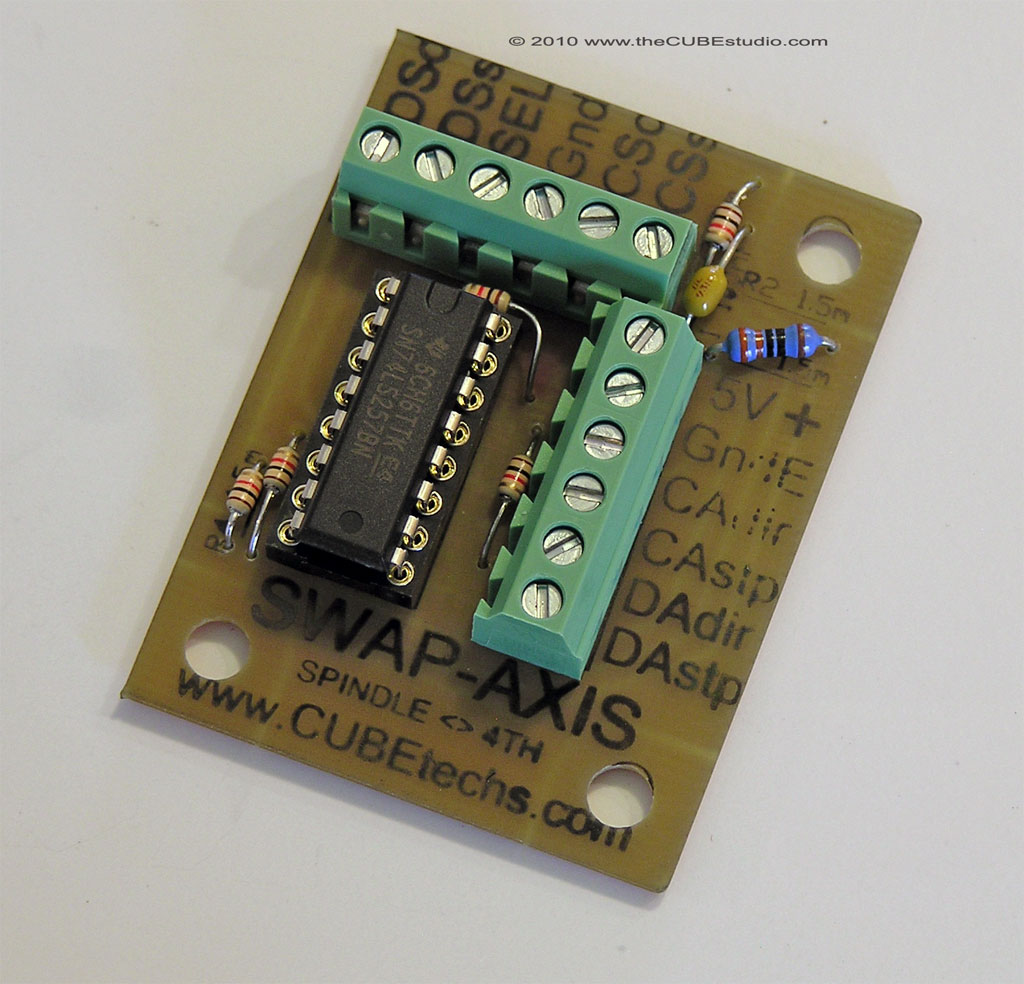

The new 'SWAPAXIS' hardware board is completed and working!This should work with any CNC software and also with the Smoothstepper. The rehoming macro still works, but the swapaxis command is now superfluous, of course and will be removed.

I extend an offer to Hood, who has helped me a lot with my projects, to receive a free swapaxis board to keep in exchange for testing it with smoothstepper. If Hood declines then the offer is open to anyone with a smoothstepper who is willing to do some testing.

I am currently accomplishing the axis swap via the M9 command for flood cooling. I have the output mapped to the SwapAxis board. ANY output will work fine, I just used a 'standard' CNC output that every system should have available.

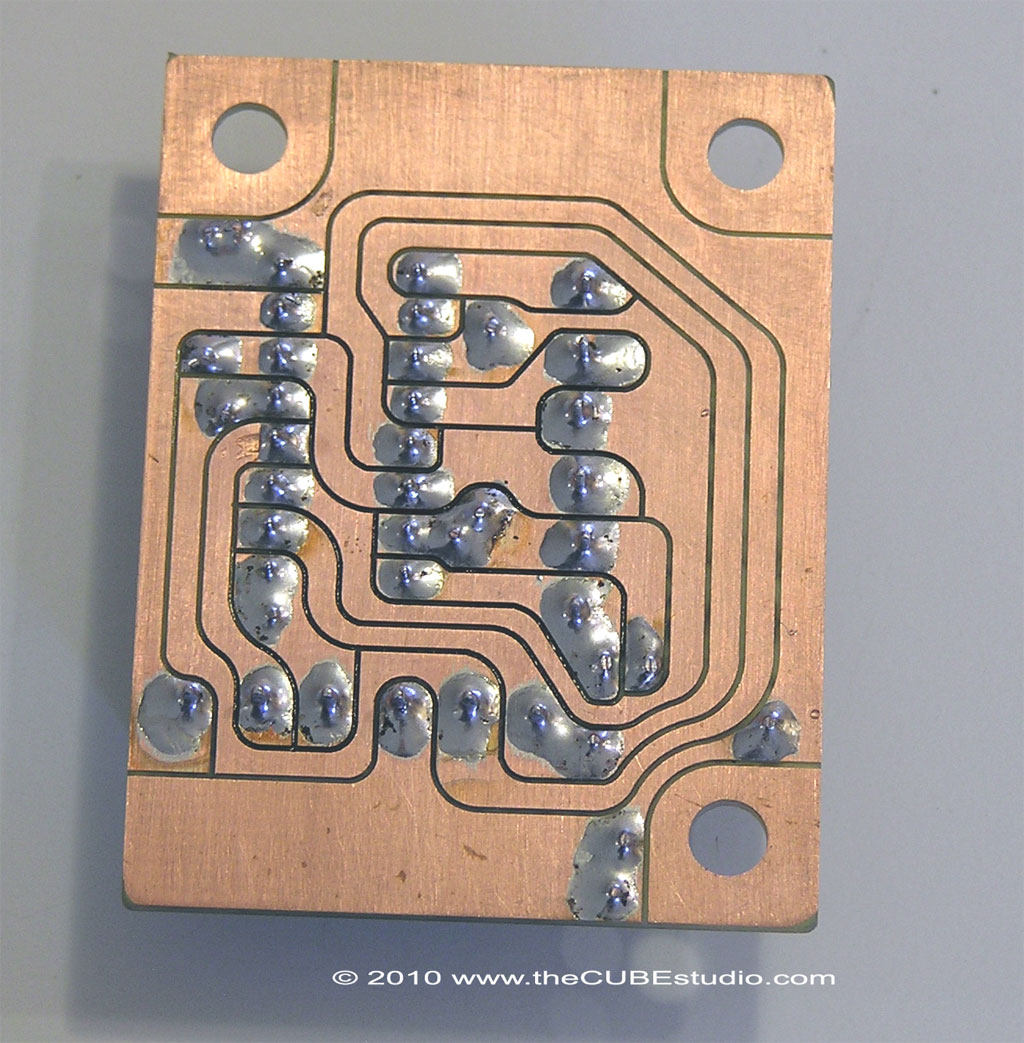

Photos of the little PC board follow. The .032" end mill I normally use was too wide for the very small traces needed for this little guy, so I did my first rounting with a 30 degree router bit to cut the traces. NOw I have 'ebgraver fever' and I want to engrave everything. Trying to figure out how to fixture the dog . . LOL!!