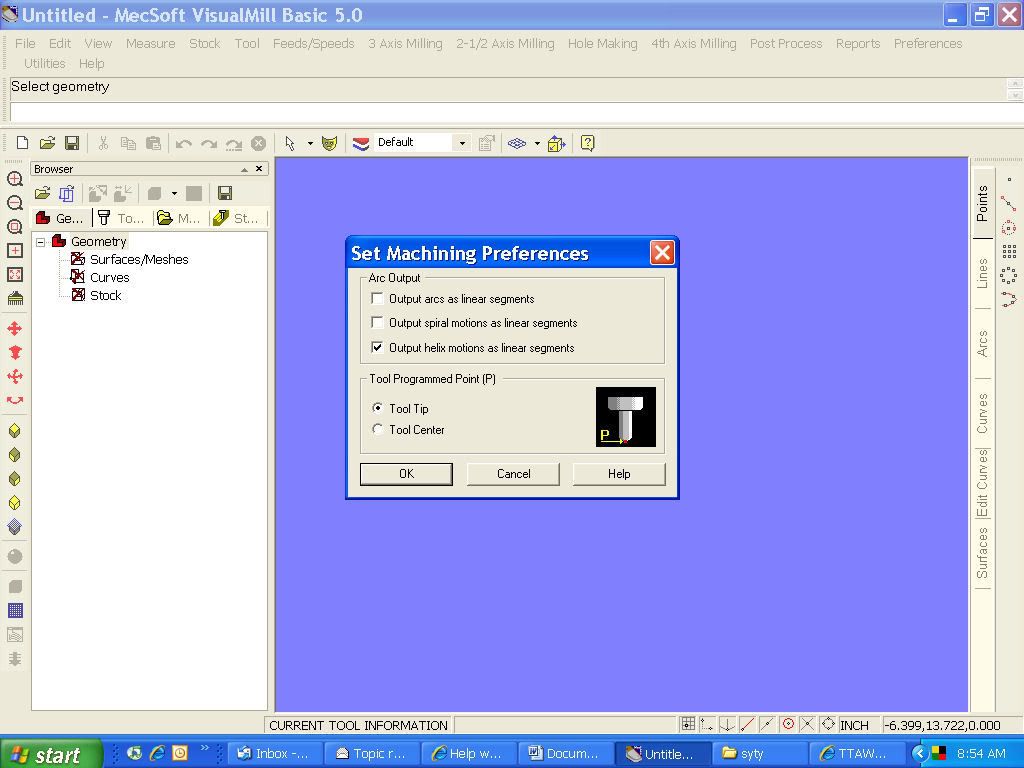

After getting the error I go back the machining preferences and make changes until Mach will take the code.

Here are the changes.

Here is the code that I ended up useing for the job.

I cut this code very short so I could post it.

G00 G43 G40.1 G17 G80 G50 G90

G20

(Hole Pocketing)

M6 T1

G43 H1

M03 S1750

G00 Z0.1875

X0.0333 Y1.2287

G01 Z0.0250 F5.0

X0.0357 Y1.2318 Z0.0238

X0.0382 Y1.2360 Z0.0222

X0.0404 Y1.2405 Z0.0206

X0.0421 Y1.2451 Z0.0190

X0.0433 Y1.2499 Z0.0174

X0.0440 Y1.2548 Z0.0158

X0.0443 Y1.2598 Z0.0142

X0.0440 Y1.2648 Z0.0127

X0.0433 Y1.2697 Z0.0111

X0.0421 Y1.2745 Z0.0095

X0.0404 Y1.2791 Z0.0079

X0.0382 Y1.2836 Z0.0063

X0.0357 Y1.2878 Z0.0047

X0.0327 Y1.2918 Z0.0031

X0.0293 Y1.2954 Z0.0016

X0.0256 Y1.2987 Z0.0000

X0.0215 Y1.3016 Z-0.0016

X0.0172 Y1.3041 Z-0.0032

X0.0127 Y1.3061 Z-0.0048

X0.0080 Y1.3077 Z-0.0064

X0.0032 Y1.3088 Z-0.0080

X-0.0017 Y1.3094 Z-0.0096

X-0.0067 Y1.3095 Z-0.0111

X-0.0116 Y1.3092 Z-0.0127

X-0.0165 Y1.3083 Z-0.0143

X-0.0213 Y1.3070 Z-0.0159

X-0.0259 Y1.3051 Z-0.0175

X-0.0303 Y1.3029 Z-0.0191

X-0.0345 Y1.3002 Z-0.0207

X-0.0384 Y1.2971 Z-0.0222

X-0.0419 Y1.2936 Z-0.0238

X-0.0451 Y1.2898 Z-0.0254

X-0.0479 Y1.2857 Z-0.0270

X-0.0503 Y1.2814 Z-0.0286

X-0.0522 Y1.2768 Z-0.0302

X-0.0537 Y1.2721 Z-0.0318

X-0.0546 Y1.2672 Z-0.0334

X-0.0551 Y1.2623 Z-0.0349

Y1.2573 Z-0.0365

X-0.0546 Y1.2524 Z-0.0381

X-0.0537 Y1.2475 Z-0.0397

X-0.0522 Y1.2428 Z-0.0413

X-0.0503 Y1.2382 Z-0.0429

X-0.0479 Y1.2339 Z-0.0445

X-0.0451 Y1.2298 Z-0.0460

X-0.0419 Y1.2260 Z-0.0476

X-0.0384 Y1.2225 Z-0.0492

X-0.0345 Y1.2194 Z-0.0508

X-0.0303 Y1.2167 Z-0.0524

X-0.0259 Y1.2145 Z-0.0540

X-0.0213 Y1.2126 Z-0.0556

X-0.0165 Y1.2113 Z-0.0572

X-0.0116 Y1.2104 Z-0.0587

X-0.0067 Y1.2101 Z-0.0603

X-0.0017 Y1.2102 Z-0.0619

X0.0032 Y1.2108 Z-0.0635

X0.0080 Y1.2119 Z-0.0651

X0.0127 Y1.2135 Z-0.0667

X0.0172 Y1.2155 Z-0.0683

X0.0215 Y1.2180 Z-0.0698

X0.0256 Y1.2209 Z-0.0714

X0.0293 Y1.2242 Z-0.0730

X0.0327 Y1.2278 Z-0.0746

X0.0357 Y1.2318 Z-0.0762

X0.0382 Y1.2360 Z-0.0778

X0.0404 Y1.2405 Z-0.0794

X0.0421 Y1.2451 Z-0.0810

X0.0433 Y1.2499 Z-0.0825

X0.0440 Y1.2548 Z-0.0841

X0.0443 Y1.2598 Z-0.0857

G17

G03X0.0432Y1.2701I-0.0498J0.0000Q0.0937

X-0.0541Y1.2495I-0.0487J-0.0103

X0.0432Y1.2701I0.0486J0.0103

G01 X0.0256 Y1.2986

Y1.2987 Z-0.0858