Progress.

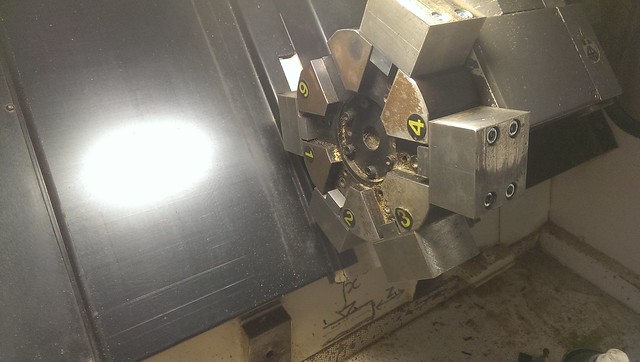

Covers on and blocks ready for boring

Covers on and blocks ready for boring by

mc_mtb, on Flickr

I had a bit of an extended run on needing to make bits, so had been suffering from a chicken and egg situation, in that the little lathe takes too much time/manual input to make the bits, so I've not had time to get this up and running, and then when I have had time, things have stalled due to needing some stupid part I should of ordered weeks ago.

The tool holders have now been milled to the correct height, and the other faces tidied up to look a bit neater. Took a couple weeks to get hold of suitable length bolts, as they need to be a specific length, and the supplier sent them to the wrong address.

I was going to risk just relying on the grub screws to hold the X servo pulley in place, however after I realised just how much effort it takes to get all the slideway covers off/on, and that I really want to minimise knocking any of the tooling of line by anything slipping, I ordered up a suitable broach set, and took the pulley back of.

Everything is now back on how it should be.

I'll take the Z servo pulley of and broach it at some point, but I'm in no rush as it's far easier to get into and not as critical if it does slip.

I've got a dedicated computer setup now, so have been working on the final coding, during which I discovered an issue with the PLC ladder causing the toolchanger to go into an endless spin if an invalid position was requested. That's now sorted, so that it shouldn't do anything if an invalid position is requested, and if it does somehow go into an endless spin, it should stop after 10 seconds (I could probably reduce this, as the maximum change time should be sub 3 seconds).

Thanks to Hood, I've also added some extra lines to the tool change macro so any program should halt with a warning message if an invalid position is requested during a program.

Main things I have left to do are bore the tool holders, and properly tune the servos. I done a quick tune earlier, and have the X-axis holding sub 50 pulses, and the z about 14 pulses, but I think X should be better.

I also need to make a proper stand, but that won't stop it working!