Whilst lounging about on holiday last month, this popped up on the radar

New Toy

New Toy by

mc_mtb, on Flickr

Once back from holiday, I had been planning to order all the bits to get my Matchmaker mill up and running, then look at getting something bigger to replace my little Conect lathe, however this Cyclone happened to pop-up just before I ordered anything.

My main reason for purchasing it, is it's a 35mm through hole version, which ties in nicely with my future plans. It also comes with a 6 position toolchanger.

Initially I was going to go a for a quick retrofit using a PLCM-E3 controller coupled with the PLCM-B1 BOB as the BOB is 24V tolerant, so connecting everything would of been reasonably straight forward, with the only other items needed being a couple stepper drivers, a bridge rectifier, and a big capacitor to give me a power supply for the steppers, however the PLCM stuff was out of stock in the UK with a lead time of two weeks. Also some reading up that the PLCM doesn't support threading, and all english pages disappearing from their website put me of using it.

Instead I've opted for a bit more involved retrofit, using the Dynomotion KFlop+Kanalog I had already bought for the mill, and fitting servos.

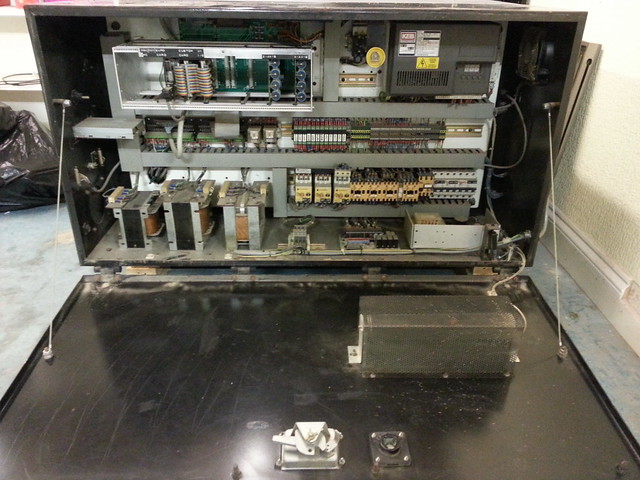

Here's the control cabinet prior to delivery -

Electrics as Delivered

Electrics as Delivered by

mc_mtb, on Flickr

The original setup used an Optimised Controls rack fitted with a Eurostep controller, and rack mount Parker SD15 drives.

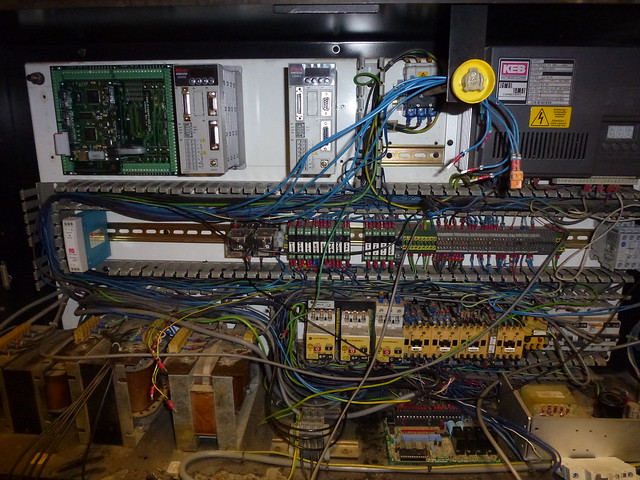

I spent some time today removing the old rack along with the wiring I know I won't need, and getting the Kanalog and servo drives mounted in place. I also managed to get an extra single phase contactor for the servo drives in place and connected into the E-Stop controlled supply.

As of this evening, this is how the control cabinet sits-

Out with the old, in with the new

Out with the old, in with the new by

mc_mtb, on Flickr

I'll hopefully start getting things wired up tomorrow.