Hey Gerry

My current setup on the acceleration is 2000mm/s2, which is pretty high. Actually, maybe acceleration is extremely high for the hard aluminium.

Regardless of acc, the sharp corners get rounded. When I reduce the CV, its better.

I dont have the problems with CV as much, as all of my parts are rounded, and there are no sharp corners.

My problem is that Mach3 is making shortcuts when applied with different speeds. For example: If I run it with 30 mm, and slow it down to 50 % of feedrate, the mach starts to be more precise. If I return it back to 100%, it will not be precise again, which is disturbing thought.

Also, I am milling a socket which is 6.2 in diameter, with 6 mm end mill, and that sockets are making troubles, not fitting in the JIG. Roughing and finishing passes, but also finish pass is also a bit high speed.

I could be missing something. What I will try, is to make smaller cutter, and make another jig with new setup of CV.

What about EMC2 or Mach4?

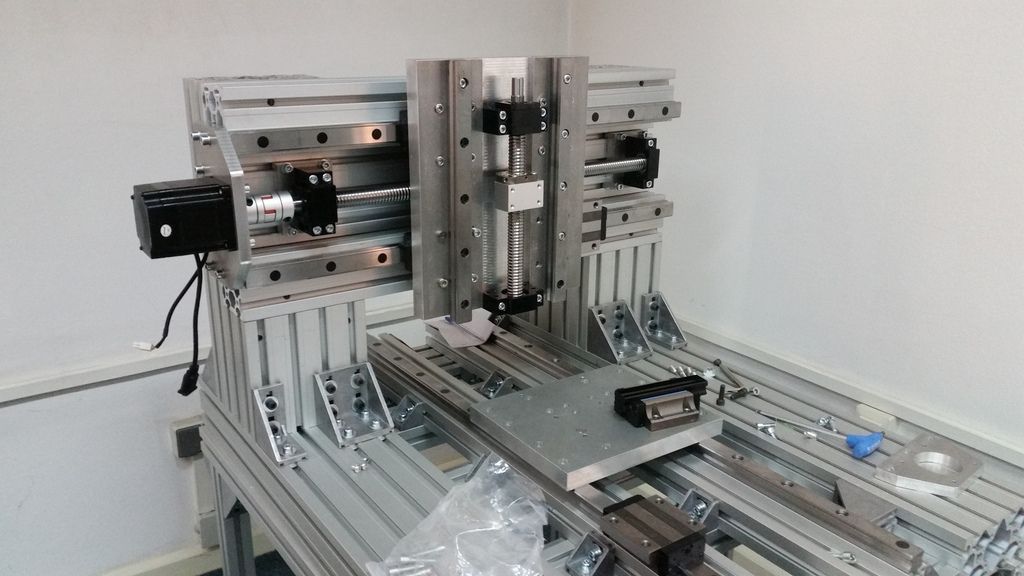

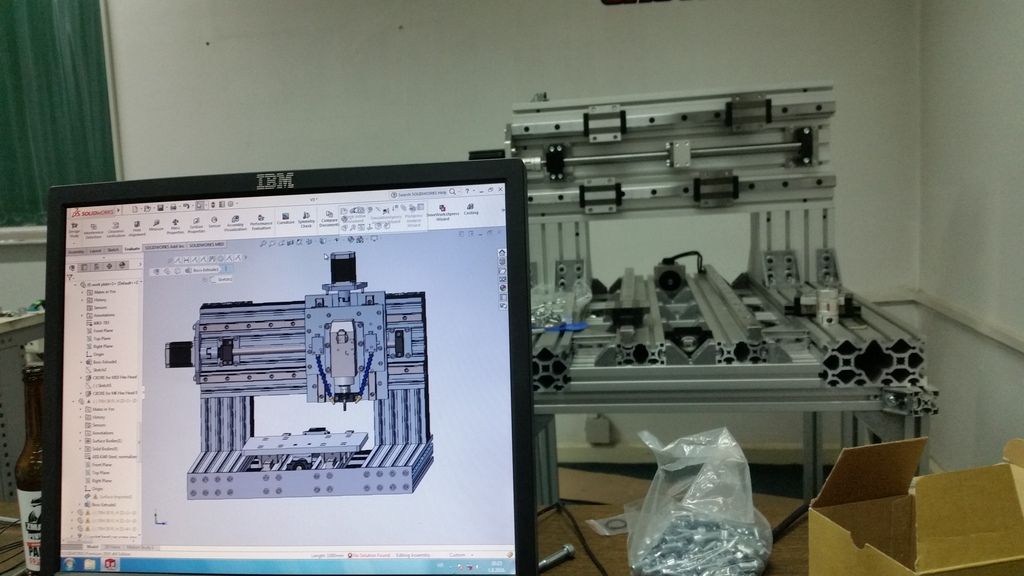

Image will show you.

First two are my products, and last two is machine while being built.

Will also upload the video of milling.