Hi all,

recently obtained a Denford Orac lathe and PC running Mach 3 ... It came from a firm that produced items in aluminium and so spindle speed wasn't an issue (nor was the ability to reverse the spindle) - and so I've completed the task (as all the break out boards and motor control was in situe, just needed the additional wiring to make it operational)

The problem I've run into is trying to do constant surface speed - mathematically it is always incorrect if my understanding of G-coding is correct.

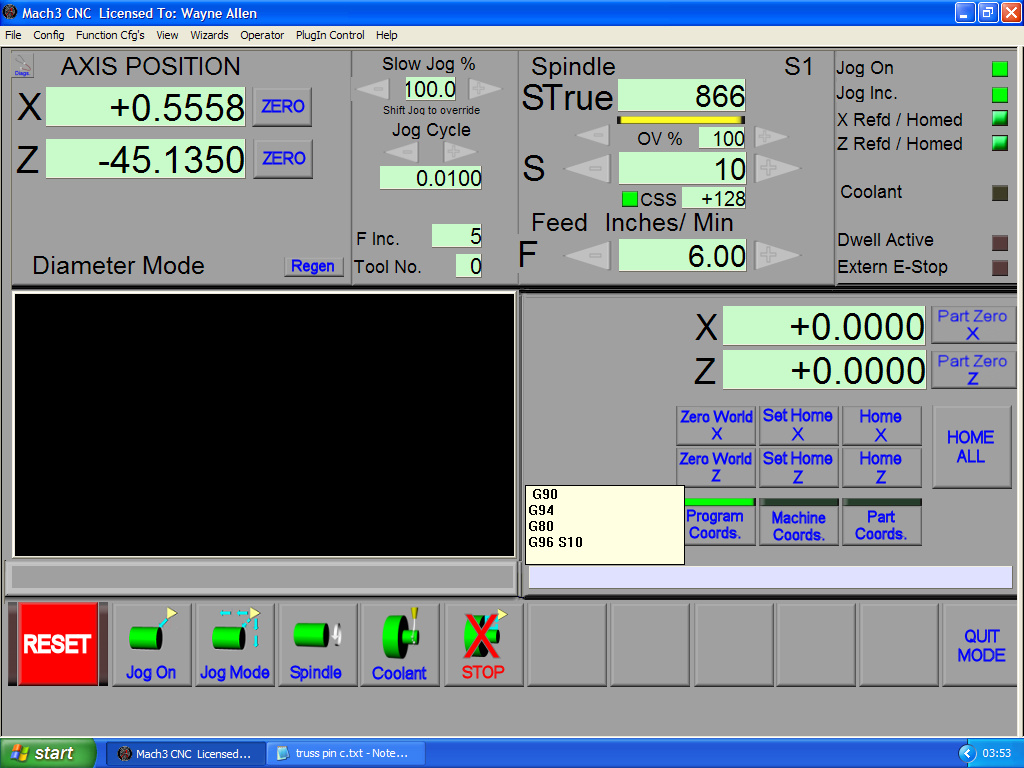

G96 = constant surface speed in units per minute ... Mach 3 is running in mm as specified in the G-Code 'header', so my understanding is that G96 S20 should give a surface speed of 20m per minute however, when working out Speed (from Mach 3 DRO) in rpm x diameter x pi = something nowhere near the supposed surface speed!!!

The Orac instructions claim that the spindle can rotate upto 2000rpm, but this turns out to be an impossibility (unless I'm missing something very obvious) as the motor is rated at 1400 rpm, and the belt drive gives a step down speed of approx 0.6, so the max spindle speed can only ever be 840 rpm!! - Though the pulley ratio is irrelevant to one extent as the speed / timing / index sensors are on the spindle, so should always give the true spindle rpm?

Anyway I digress - I added a screen shot of Mach3 running in constant surface speed, and I'll let you do the maths and see if I'm missing something, or if there is indeed something wrong.

Please help as it's been 3 days of headache and measuring and re measuring and taking the belt drive off to measure pulley diameters and circumfrences and maths and countless scraps of paper calculations and I seem to be no further forward