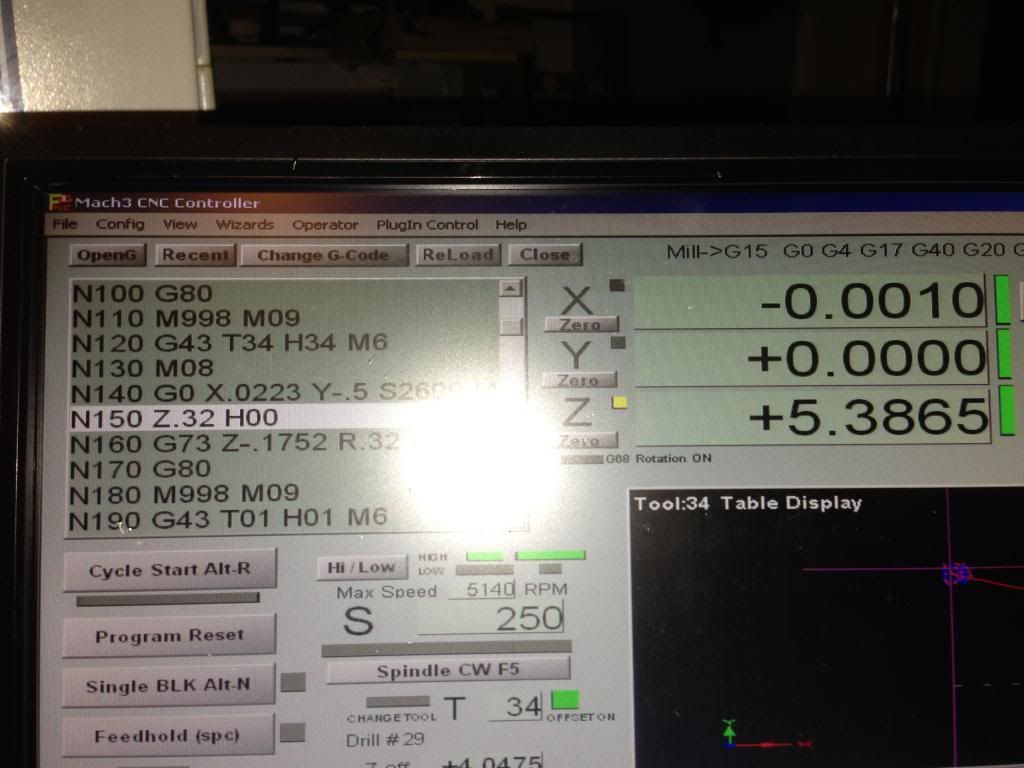

I had a problem with my controller last night. I loaded a program, and it ran without incident. I put a fresh piece of stock in the vise, and hit “Cycle Start” again. It ran through the first tool without any problems. After the tool change to the 2nd tool, the spindle speed changed to 250 rpm, and all three axis moved to 0,0,0, ignoring the tool length offset, which crashed the tool into the vise.

This happened to me once before, several months ago. Since then it has all operated as normal.

I don’t know how easy it is to tell in the picture, but the last commanded line was X.0223 Y-.5 S2600 and you can see on the display X&Y are zero and the speed is 250. The Z shows a large number because I jogged the Z axis up so the tool was out of the vise.