301

General Mach Discussion / Re: Why not G54 instead of G52 for multiple parts?

« on: January 06, 2010, 04:23:09 PM »

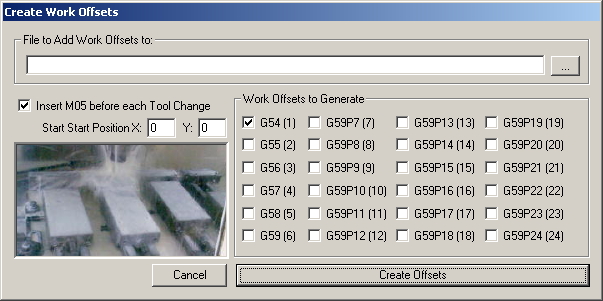

I created a Work Offset Program that reads in your G code and creates as many Work Offsets as you select while limiting the number of tools changes for each offset.

http://www.machsupport.com/forum/index.php/topic,6129.msg89737.html#msg89737

Hope this helps,

JH

http://www.machsupport.com/forum/index.php/topic,6129.msg89737.html#msg89737

Hope this helps,

JH