Time for an update on the ORAC

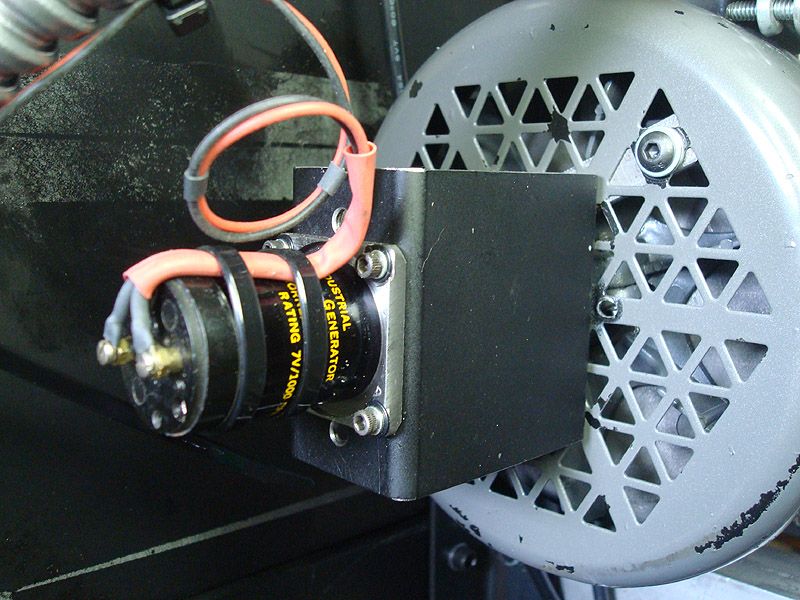

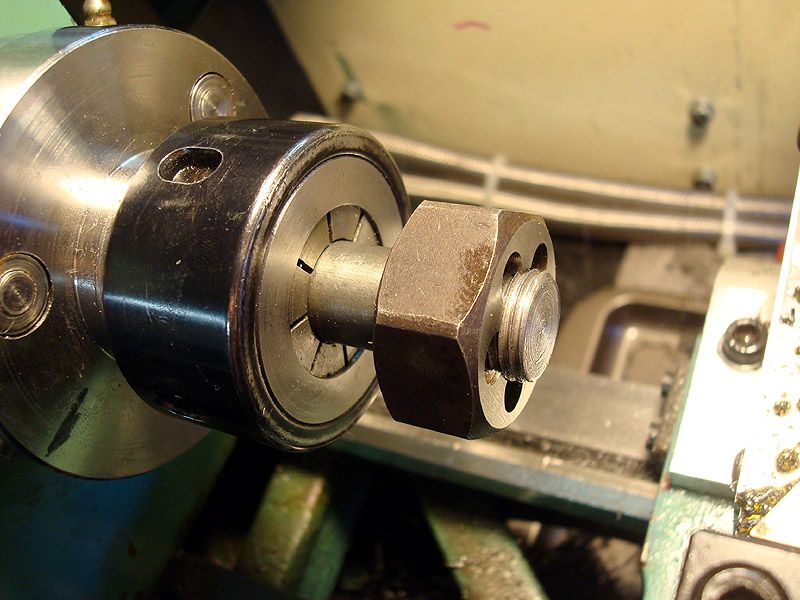

Added a tach–generator to input a feedback signal into the KB speed control to stabilize the spindle speed for better threading. KB says 1% variation over its 50:1 speed range using tach feedback and the results were great. Picked up a used 7V/1000 rpm Servo-Tek tach for peanuts on ebay and cobbled together the nec stuff to mount & drive it off the back end of the Baldor.

The coupler is just a bit of soft rubber tubing with a couple o-rings slid on to make sure it doesn’t slip.

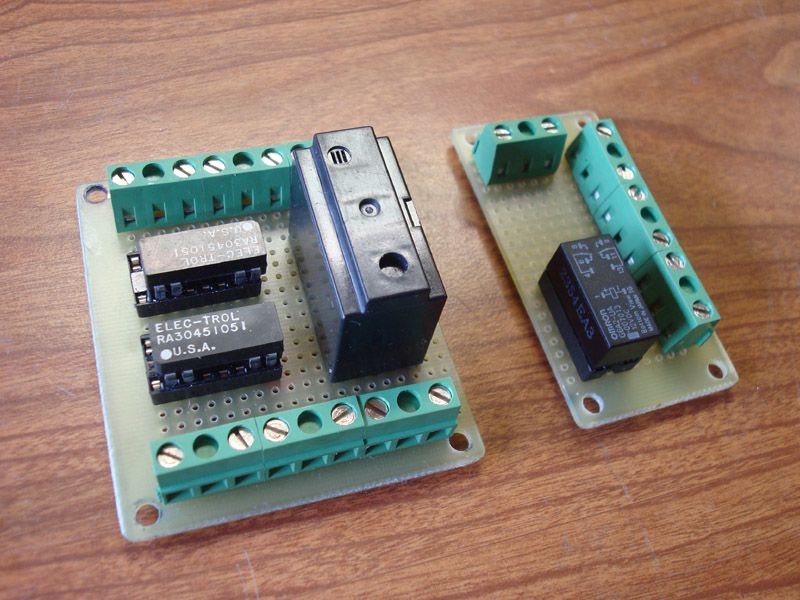

The KB instructions cautioned that correct polarity must be observed and if spindle reversing is used, the tach input signal polarity must be reversed along with spindle motor reversal. I made up a couple relay boards to do that and to switch power to the 12V cutting oil pump motor. The DPDT polarity reversing relay is in series with the tach output triggered by a 5V relay hooked to the B.O.B. and pulled in only upon M4 command.

One board mounts inside the base enclosure and (a) sends a 12V signal to the DPDT relay on the other board in the speed control enclosure and (b) switches power on & off to the cutting oil pump. The bigger pump relay in the pic was snagged off an A/C control board they were throwing out at work. I love making stuff using free parts!

There was a reverse polarity spike when braking to a stop after a reverse command so I stuck in a couple diodes after the DPDT relay. That stopped the funny noise from the KB when stopping after running the spindle in reverse.

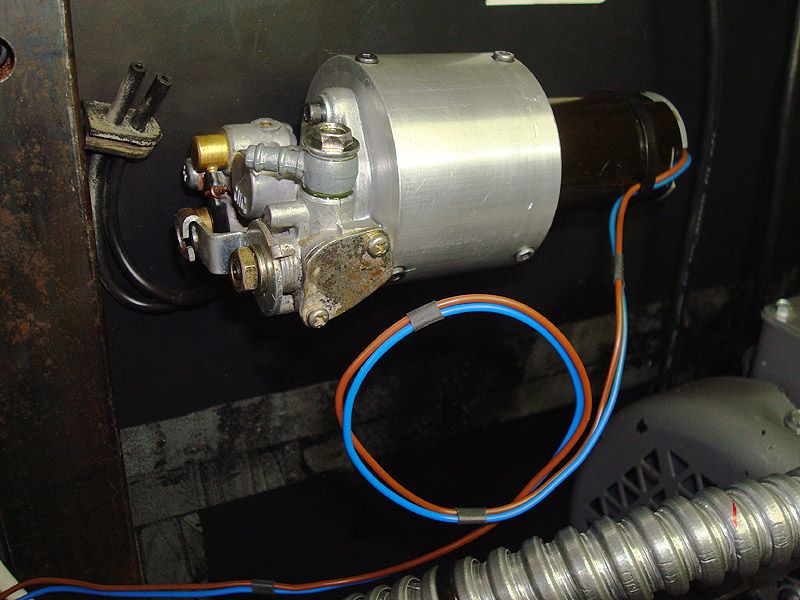

Here’s the cutting oil pump I rigged up using a 12V auto sunroof blind motor (another freebie from work) and a Suzuki 125cc 2-stroke oil injection pump. I tried a 250cc pump but it put out too much oil. The rate is easily adjustable using the rotary valve control that used to be connected to the throttle but I found that all the way back to the idle position gives the steady drip – drip – drip I was looking for. Plenty good for keeping the work & the tool wet but no so much that it makes a huge mess.

The 250 pump has 2 outlets & I may make another motor drive & relay control for it later to lube the ways & ballscrews. The ORAC relies on the operator oiling it frequently so automatic oiling would be great.

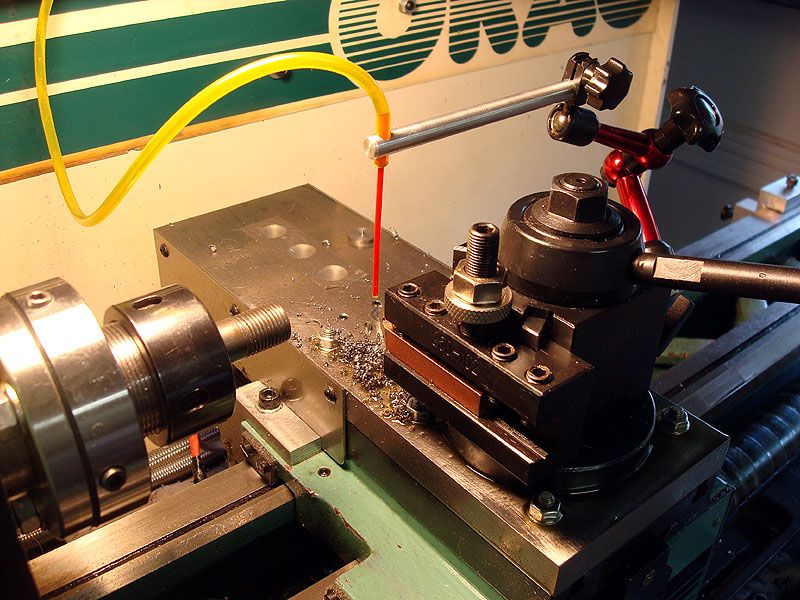

Finished installation pic. The reservoir is a plastic1 pint brake fluid bottle. No need for a huge tank with the slow drip-drip-drip feed.

I used Tygon tubing off ebay to plumb it as the stuff is very resistant to most oils and is pretty cheap. The flexible plastic nozzle is an aeresol brake cleaner straw and I used a mini DTI stand to position it. Quick & easy to get the nozzle right where it’s needed.

I’m real happy with how well the oiling system works. It starts dripping immediately on command and also stops instantly with maybe one solitary drip after it’s turned off. I’m not planning a major rebuild to add an enclosure to support flood coolant so this method’s here to stay.

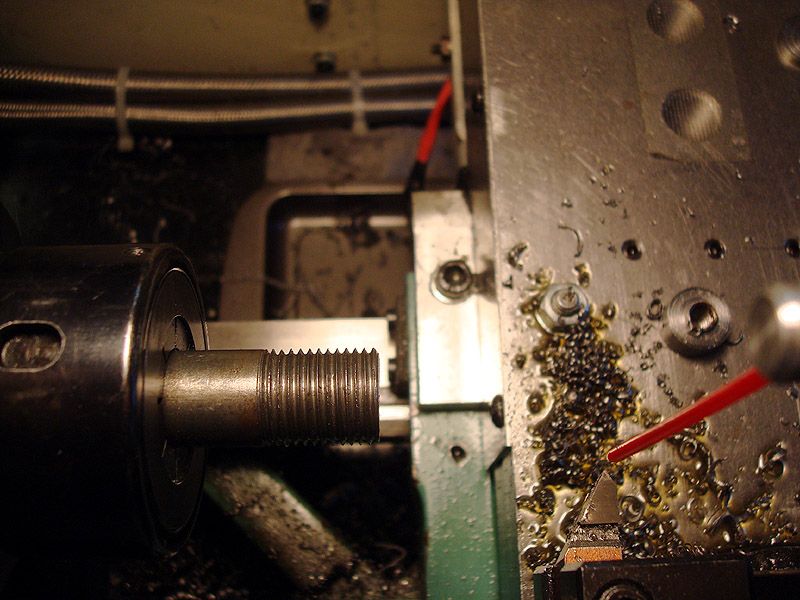

I did my 1st threading over the weekend and it came out pretty well considering the cheap-o brazed carbide tool I had on hand. I’ll get some decent inserts & a holder one of these days and should get even better results. The test was on a piece of crappy hardware store cold-rolled steel and I chose 16mm x 1.5, the only size die I had on hand close to the 5/8” stock to check the thread with.

The 300 rpm spindle speed held very steady through the whole process but my puny little stepper & control were overworked at .002” D.O.C. The die screwed on & fit snugly but the threads were ragged & looked like a few steps got lost in the struggle. The next try at .001” D.O.C. was much better.