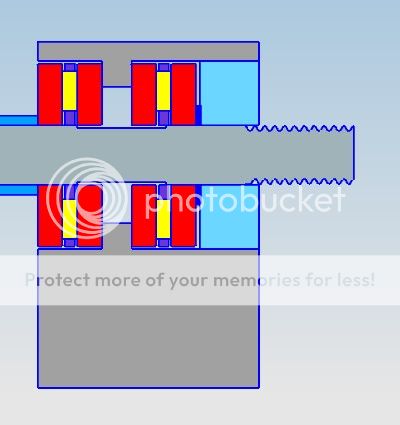

Here is the bearing housing for the X axis:

I went for a needle thrust bearings arrangement here. It is two needle thrust bearings closed from either side of a step inside the bore. They are combined with a deep groove ball bearing at the end to provide axial support for the belt tension. Here is the section of the arrangement:

The reason for this over angular contact ball bearings is that angular contacts at that size are pretty limited in the axial loads they can take. The needle thrust bearings on the other hand can handle axial loads several orders of magnitude higher than the angular contacts. Preloading is fairly easy too. And as a bonus they are only a fraction of the price of angular contacts

The bearing housing will be mounted on the back of the carriage (as the motor is going to sit on the back). There are M6 mounting holes on the back of the carriage seen on the carriage picture.

The two bosses on the bearing housing are for mounting the motor mounting plate.

By the way, it's not shiny in the picture as it got treated with a light solution of phosphatic acid to prevent corrosion. Works well.

Dan