Hello everyone!

Ok today after looking at my CNC machine, and having a quick chat with Mr Tweakie, the machine really does need an update...

...and besides, it’s always fun to build right...right?

I could get a bigger machine bed/cutting area but more importantly more of a stable rigid machine!

For the size of the machine, I only get a 40mm x 30mm cutting area; this is for a few reasons:

Update 1 –Flying Gantry - In design stageThe ‘over-hang’ from the flying gantry is not enough – Currently my Kress Milling tool will over hang the front of the machine by about 100mm! Yes allot of wasted area huh?

So my new design will offset that, and the gantry up rights will lean further back to salvage back that wasted area! Hopefully the Kress will sit bang in the middle

Update2 – Backlash – In design stageBacklash – everyone loves backlash, well now that I want to do some relief work, and more accurate work (maybe a little bit of really soft aluminium’s/brasses)

0.8mm in the Z Axis

1.2mm in the Y Axis

1.3mm in the X Axis....

...Is now far too much

Currently my machine uses TR12x3D Trapezoidal Spindles with LRM12x3D Trapezoidal Nuts

(From

www.Worldofcnc.com (Great People, Great Service)

So, adding some sort of anti-backlash device to the brass Nuts is the way forward here? Thoughts?

I would love to go ball screw with Zero backlash – but currently, i just do not have the funding for such a jump.

Update3 – Rigidity – Part A -In design stageMy machine is based around 25mm marine ply, solid stuff! I’m just wondering on how much it has warped over time! As usual, i would love to build an 80x20 aluminium machine, but sigh, cost! Plus i got allot of the marine ply free! Bonus!

Here you can see my machine:

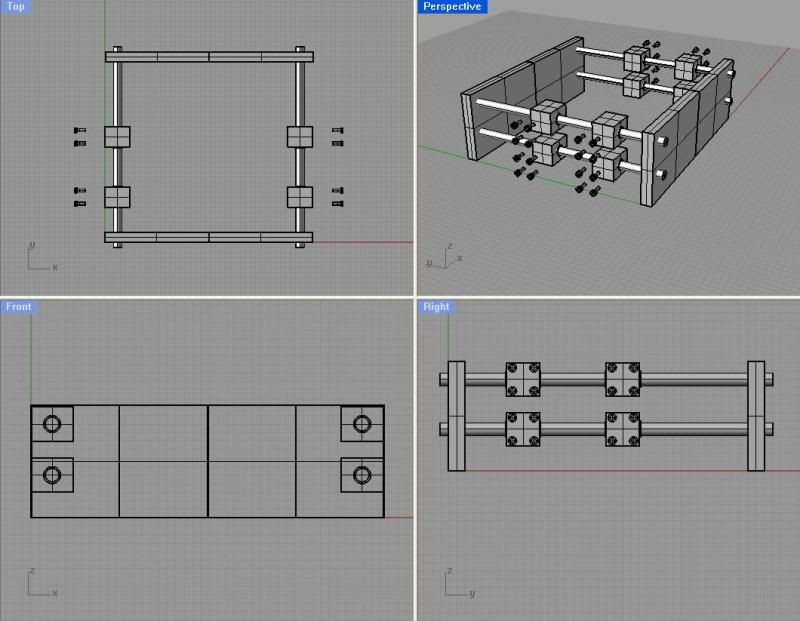

Notice that i have only 6 grounded solid steel linear rails, and only 2 linear pillow blocks per side, I'm thinking that because the flying gantry and Z Axis is so darn heavy, I’m wondering if this dips in the middle of the movement!

I’m thinking of added an extra 2 pillow blocks to each side of the gantry to overcome this a bit better, and to make it more ridged.

I like the way the Fireball machine looks, and might try and model a new machine off one like it!

Thoughts on both types of design?

One above and below or side by side?

(Please ignore my rubbish CAD drawings)

Also notice that i don’t have a bottom ‘Bed’ the weight of the whole thing could push the whole machine out – that I will have to fix somehow!

Update3 – Rigidity – Part B -In design stageNow if you look at the part where the Z ‘head’ meets the Y gantry, I get a feeling that the Z axis is top heavy, you can just notice where I have a bearing behind the Z axis push the bottom of the Axis out level, after time with a metal bearing on soft wood, its formed a channel. This must be replaced, again with an extra 4 pillow blocks and 2 linear grounded rails!

Do I do the same as above?

Update4 – Extras –-In dreamland stageThings like Auto tool zero etc..Basic stuff!

Please, any thoughts would be great – for around £120 I can get the extra rails and pillow blocks, which I could afford!

Thanks everyone!