Hi All

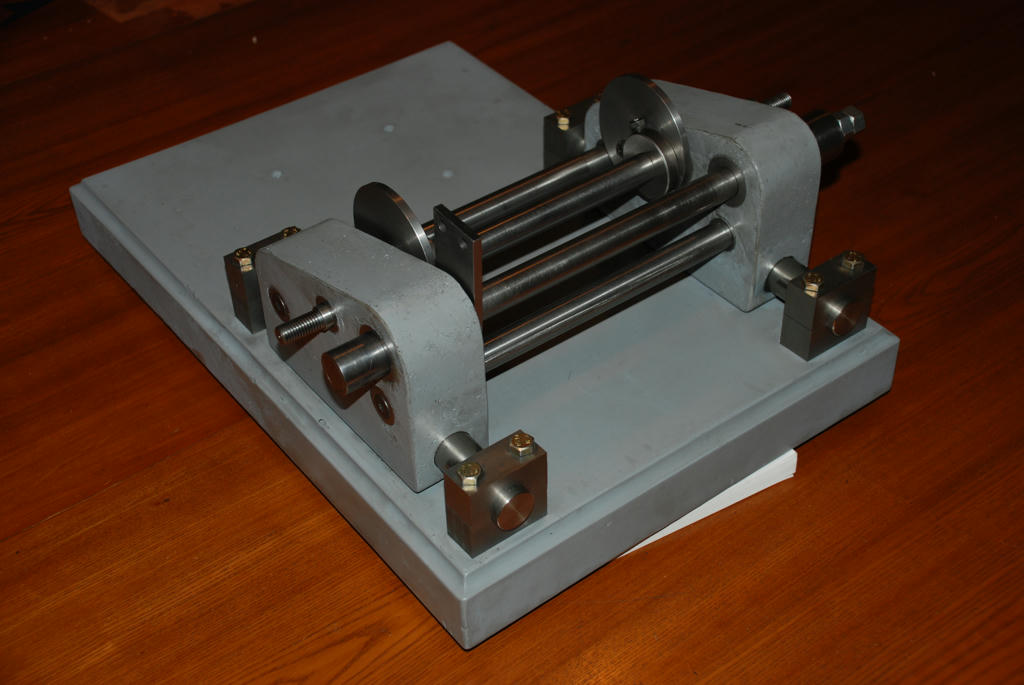

In order to learn some of the methods of using Epoxy concrete, now often called “Mineral casting” I am building a small Worden tool grinder. You will find many references on the net. It will come in handy to grind lathe tools to the correct angle; however the build is not as it was originally designed. All the sheet metal parts for the frame have been replaced by 4 Epoxy concrete castings. Most of the detailed work is now done except for the table, some graduated dials, the y axis feed, the grinding motor itself and its epoxy concrete stand.

I have been documenting the build Here: (you will need to scroll back to the start and ignore the off topic comments hmm…..)

http://www.model-engineer.co.uk/forums/postings.asp?th=51617Maybe the grinder is a bit off topic for this forum however the casting methods certainly are not. A litre and a bit of Epoxy and a bucket of aggregate and sand replaced a lot of sheet metal and made a much more rigid tool. The machine is really solid. Note the cast in place low friction bearings.

The main objective is to get some hands on experience on a small affordable project before I tackle the CNC Mill using mineral casting.

When the machine is finished I will post a set of drawings.

Cheers

John