I have a setup where I cut a lot of different diameters on my rotary axis. What I have been trying to do is set up a macro to create Z offsets and I must say I am struggling big time. I am not sure if I fully understand how offsets work.

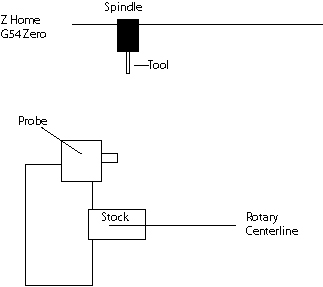

Here is a graphic of my set up:

1) I was thinking that the Z home position should be G54 zero.

2) I would then touch off on the probe.

3) I know what the distance is between the rotary center line and the probe (Cline = x).

4) I would then read a userdro where I would have previously entered the radius of the stock material.

5) I would then calculate Zoffset=(Cline - userdro)

6) I would then setvar (5243, Zoffset)

Well I get every number but the one I want. Somehow it is taking the actual offset from the home position and doing all kinds of weird stuff.

Is this thinking flawed? How should I do this. I need Z zero to be the top of the stock

TIA Dan