1

General Mach Discussion / Mach3, Leadshine MX4660, UC100 CNC motion controller and problems with Auto Zero

« on: August 14, 2016, 09:33:23 PM »

Hello all,

I am running a CNC router equipped with a leadshine MX4660, UC100-

CNC USB motion controller and Mach3. So far for a couple of month everything runs more or less OK. Now I tried to install a probe to automatically zero the tool. The probe is from cncrouterparts but basically no different to the other probes used. A piece of aluminum with a two conductor wire and a little clamp.

It is hooked up to INPUT 4 and GROUND on the MX4660. In Mach3 I am using Port1 and Pin 13 as pointed out in the leadshine manual. I used the script provided on the website of cncrouterparts.

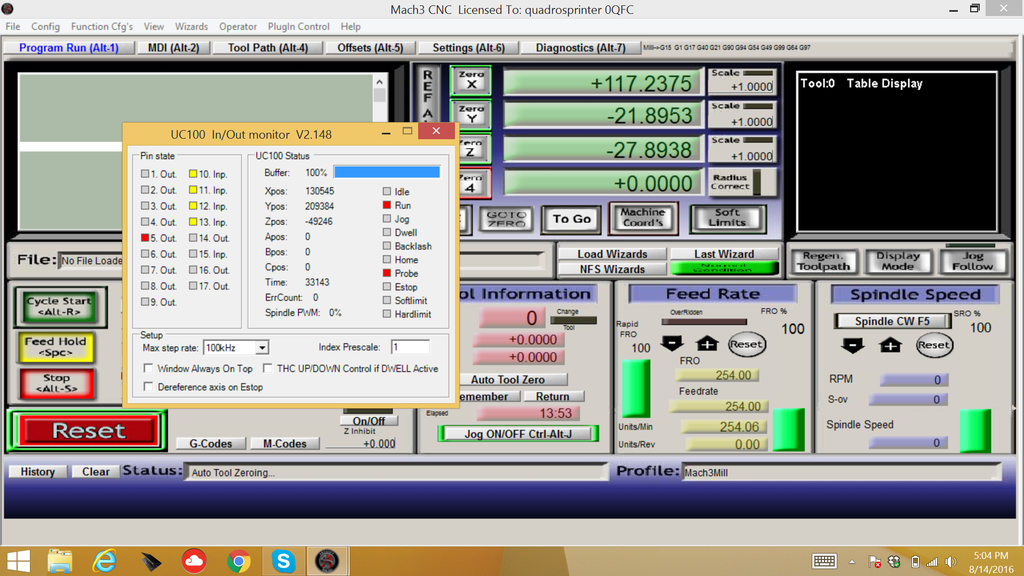

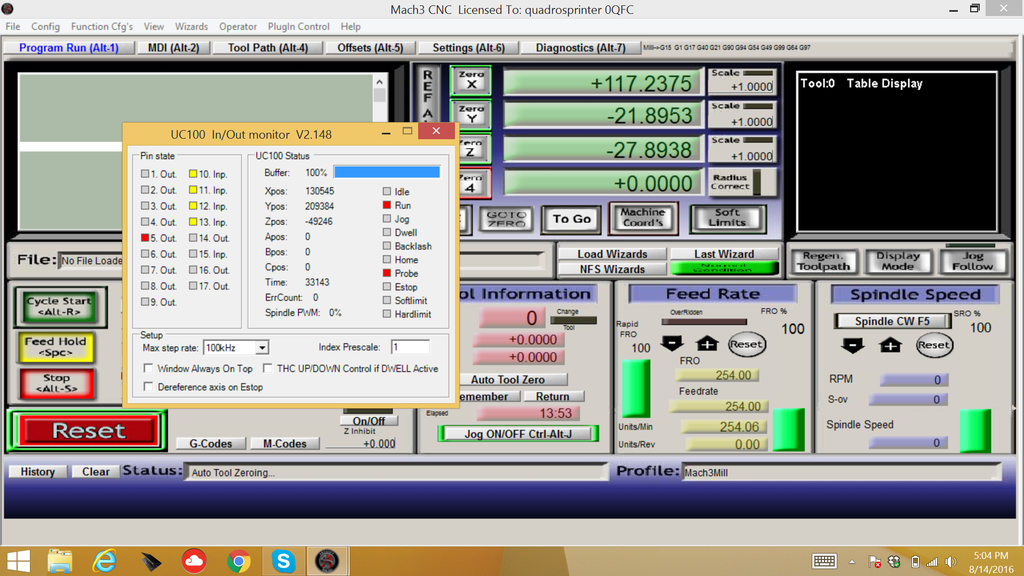

The script works nicely. If I push the "Auto tool zero" button the Z axis moves down slowly.... but .... didn't stop when hitting the probe. So I started investigating, the probe seems to be OK I tested it with a multimeter just to make sure, there can't be a lot wrong with such a probe anyhow. I tested my connections to the leadshine controller and they were OK. I looked at the UC100 IN/OUT monitor and the concerning point was that nothing was lighten up when I touched the probe with the little clamp.

As you can see in the picture, the "Probe" lights up in the moment the Auto Zero buttion is pushed, but the movement of the Z axis doesn't stop when the tool hits the probe.

So I am kinda puzzled what else could be the problem, I am kinda concerned that either the controller or the UC100 has a problem but that will be hard to find out.

Currently I think about an new motion controller.

Any thoughts? Anybody with the same setup and similar problems?

Appreciate any input.

Thanks

Chris

I am running a CNC router equipped with a leadshine MX4660, UC100-

CNC USB motion controller and Mach3. So far for a couple of month everything runs more or less OK. Now I tried to install a probe to automatically zero the tool. The probe is from cncrouterparts but basically no different to the other probes used. A piece of aluminum with a two conductor wire and a little clamp.

It is hooked up to INPUT 4 and GROUND on the MX4660. In Mach3 I am using Port1 and Pin 13 as pointed out in the leadshine manual. I used the script provided on the website of cncrouterparts.

The script works nicely. If I push the "Auto tool zero" button the Z axis moves down slowly.... but .... didn't stop when hitting the probe. So I started investigating, the probe seems to be OK I tested it with a multimeter just to make sure, there can't be a lot wrong with such a probe anyhow. I tested my connections to the leadshine controller and they were OK. I looked at the UC100 IN/OUT monitor and the concerning point was that nothing was lighten up when I touched the probe with the little clamp.

As you can see in the picture, the "Probe" lights up in the moment the Auto Zero buttion is pushed, but the movement of the Z axis doesn't stop when the tool hits the probe.

So I am kinda puzzled what else could be the problem, I am kinda concerned that either the controller or the UC100 has a problem but that will be hard to find out.

Currently I think about an new motion controller.

Any thoughts? Anybody with the same setup and similar problems?

Appreciate any input.

Thanks

Chris

Code: [Select]

[code]Message( "Auto Tool Zeroing..." )

If IsSuchSignal (22) Then

isMetric = GetOEMLED(801)

Zprobe = -3

Zretract = 1.5

ZfeedRate = 10

If isMetric = 0 Then

Zprobe = Zprobe * 25.4

Zretract = Zretract * 25.4

ZfeedRate = ZfeedRate *25.4

TouchPlateHeight = TouchPlateHeight * 25.4

End If

Call SetDRO( 2, 0.00 )

code "G31 Z" & Zprobe & " F" & ZfeedRate

While IsMoving()

Wend

Call SetDRO( 2, TouchPlateHeight )

code "G1 Z" & Zretract

End If[/code]