11

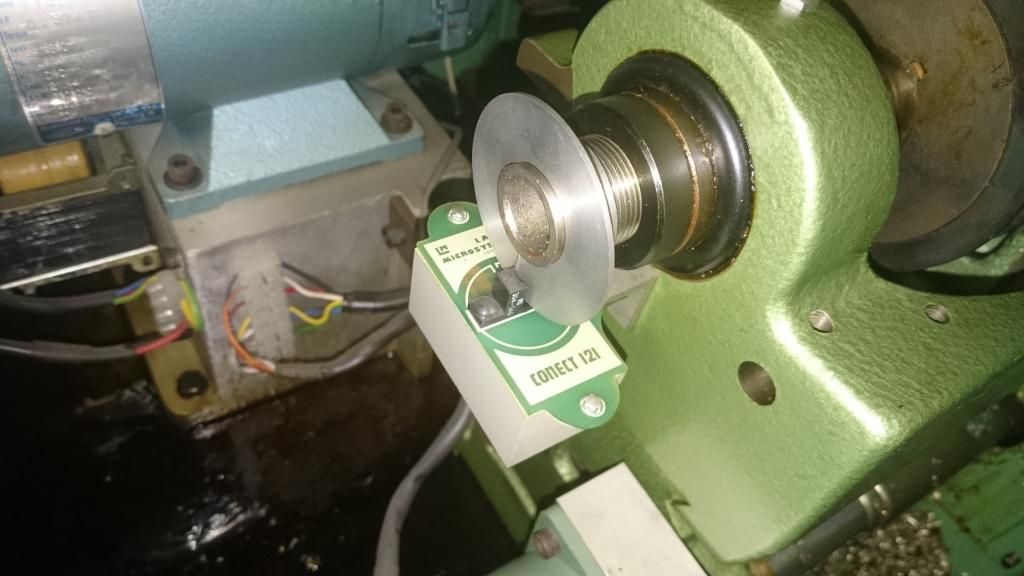

Show"N"Tell ( Your Machines) / Re: Conect 121 cnc retrofit

« on: February 14, 2015, 02:22:52 PM »

The parts are here and the wiring is underway! question, is it safe to have the cnc electronics in the Same case as the pc electronics ?I have a huge pc tower which will take it all.