291

General Mach Discussion / Re: Panasonic servo drive help

« on: May 07, 2013, 06:54:25 PM »

Definitely a new thread (since it's a different kettle of fish) would be my vote.

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

I think the PP I use puts out IK's rather than R's,Haven't gotten as far as internal arcs yet. That pain is coming later.

What problem are you having? Is it internal Arcs that are screwed?

Hood

The glass is 11.5mm thick, it is toughened and laminated glass, think 2 x 5mm toughened sheets with 1.5mm polycarb in between.Jaysus, ya gonna stick targets on those doors & do a little target practice during long runs? That ought'a take the boredom down a notch or 2!;)

Neat idea.Dohh! Thanks MC, that makes perfect sense. That's why I spend so much time here: to further my edumacation!:)

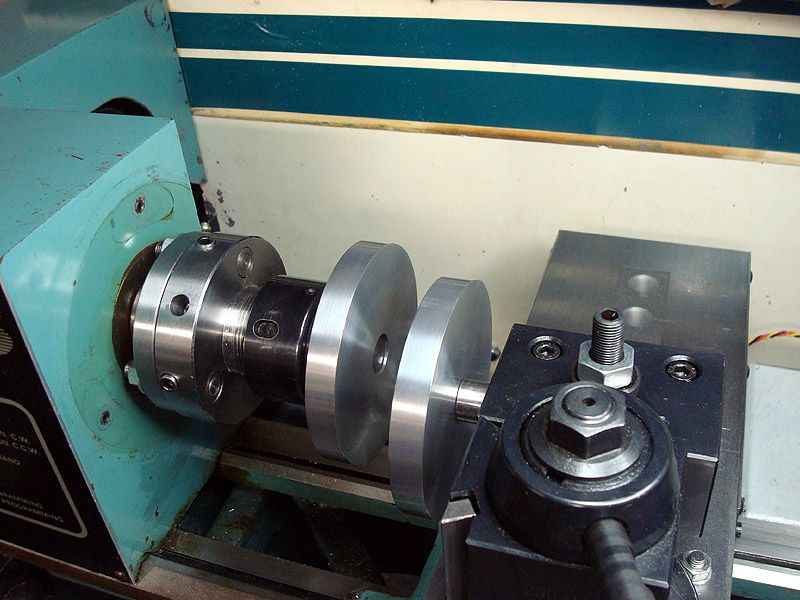

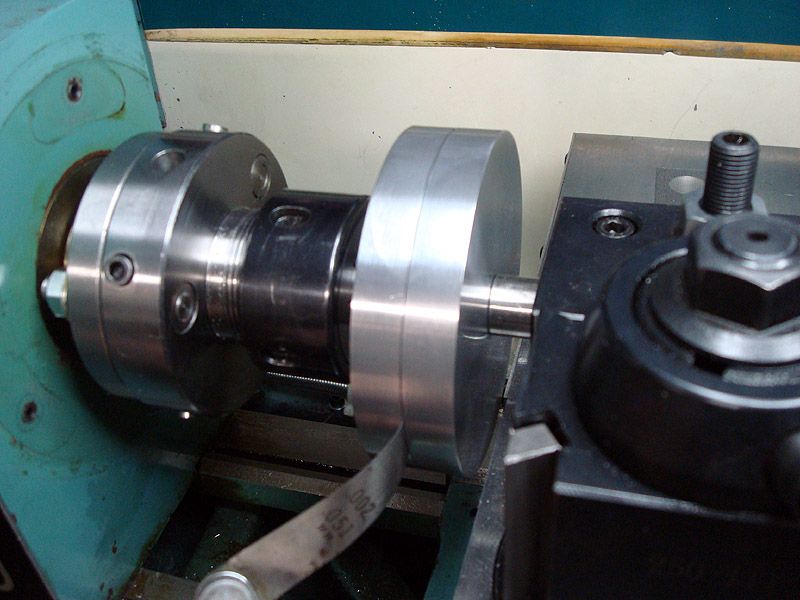

However, why not just use one disc in the QCTP, then mount a Dial guage in the collet chuck?