251

Show"N"Tell ( Your Machines) / Re: Prima Lathe conversion

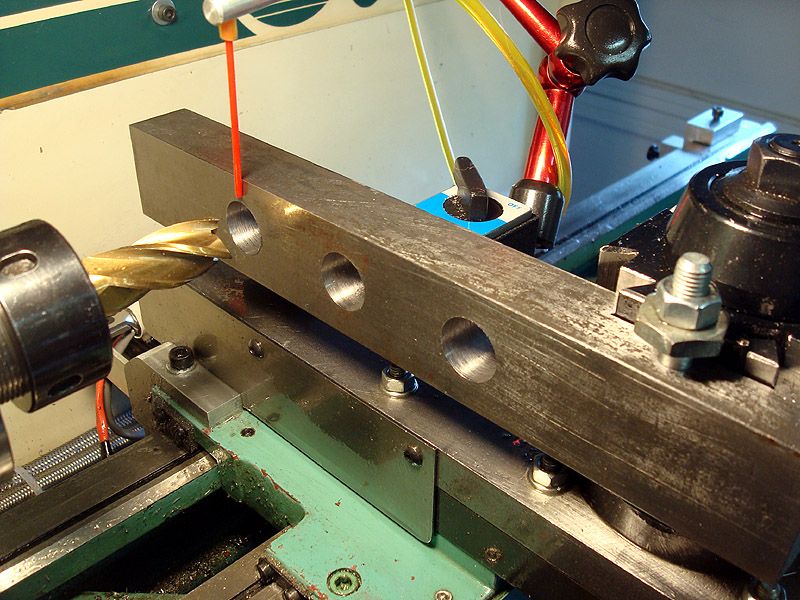

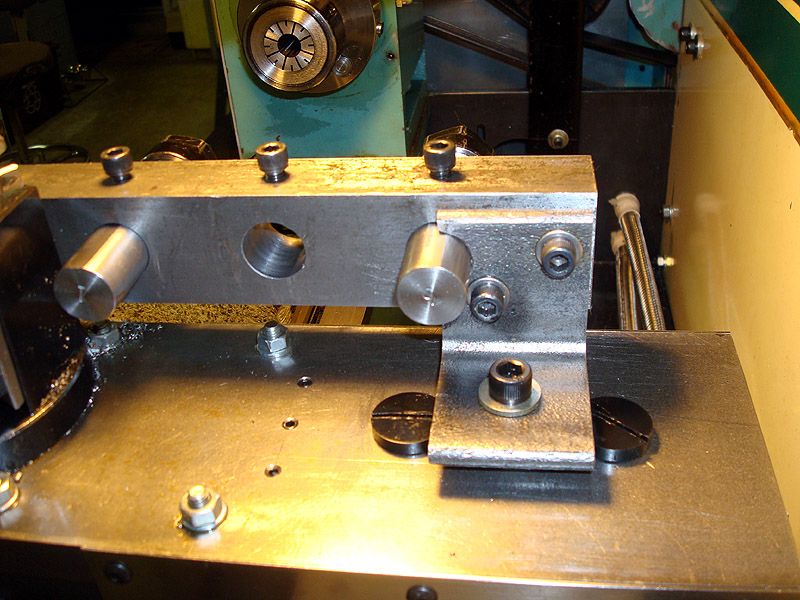

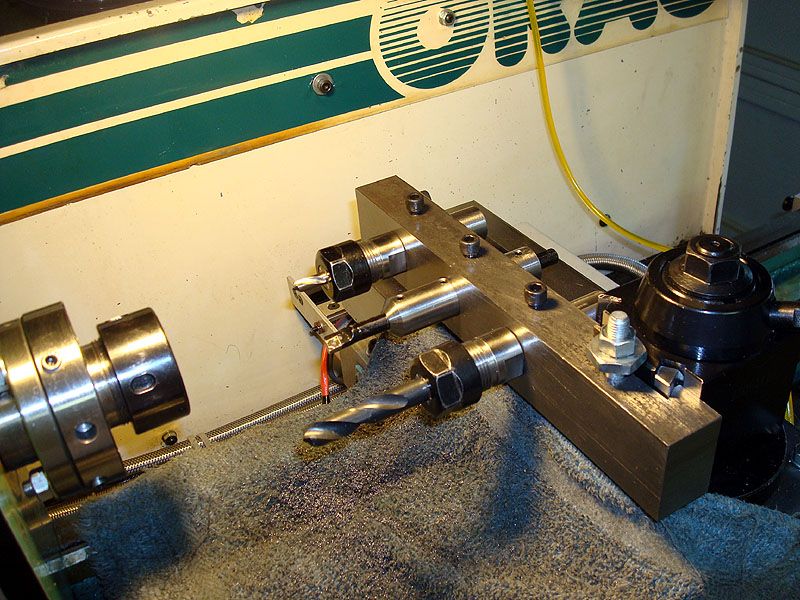

« on: September 18, 2013, 09:06:16 AM »Over the course of one month we are going to install AC servos, ball screws, limit/home switches, VFD, Spindle Encoder, Smooth Stepper, and of course Mach3.You folks have 78 hour days over there?

Just kiddiing; I'm sure you'll "git 'er done" as planned. I do hope you find time to document the build as I have really enjoyed your previous threads.