341

General Mach Discussion / Re: Has anyone used Viper Servo drivers?

« on: June 05, 2009, 02:01:33 PM »

Agreed:

1) 80Volt Limit. This alone makes it harder to find a transformer that is just less than 2:1 when making a DC Power Supply.

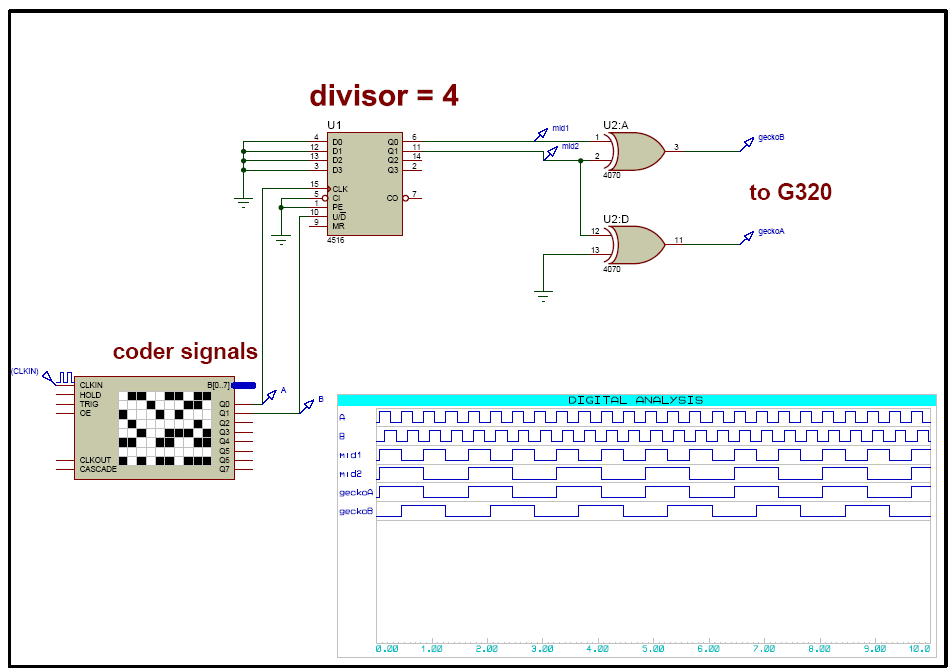

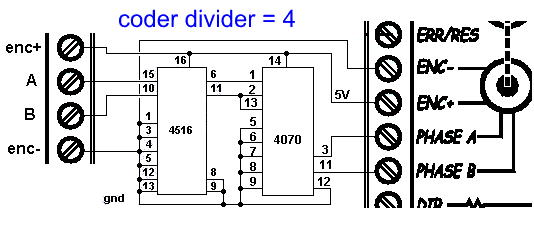

2) Fault limit of 147 (I thought it was 128) that is not scalable. This is a real pain when you use the pulse multiplier feature because the fault limit does not scale with multiplier, to get things to move without faulting your acceleration / deceleration profiles have to be slow (ie: takes longer to reach the MAX IPM during rapids)

Thanks for the info

1) 80Volt Limit. This alone makes it harder to find a transformer that is just less than 2:1 when making a DC Power Supply.

2) Fault limit of 147 (I thought it was 128) that is not scalable. This is a real pain when you use the pulse multiplier feature because the fault limit does not scale with multiplier, to get things to move without faulting your acceleration / deceleration profiles have to be slow (ie: takes longer to reach the MAX IPM during rapids)

Thanks for the info