331

General Mach Discussion / Re: Whose Fault Is ThIs?

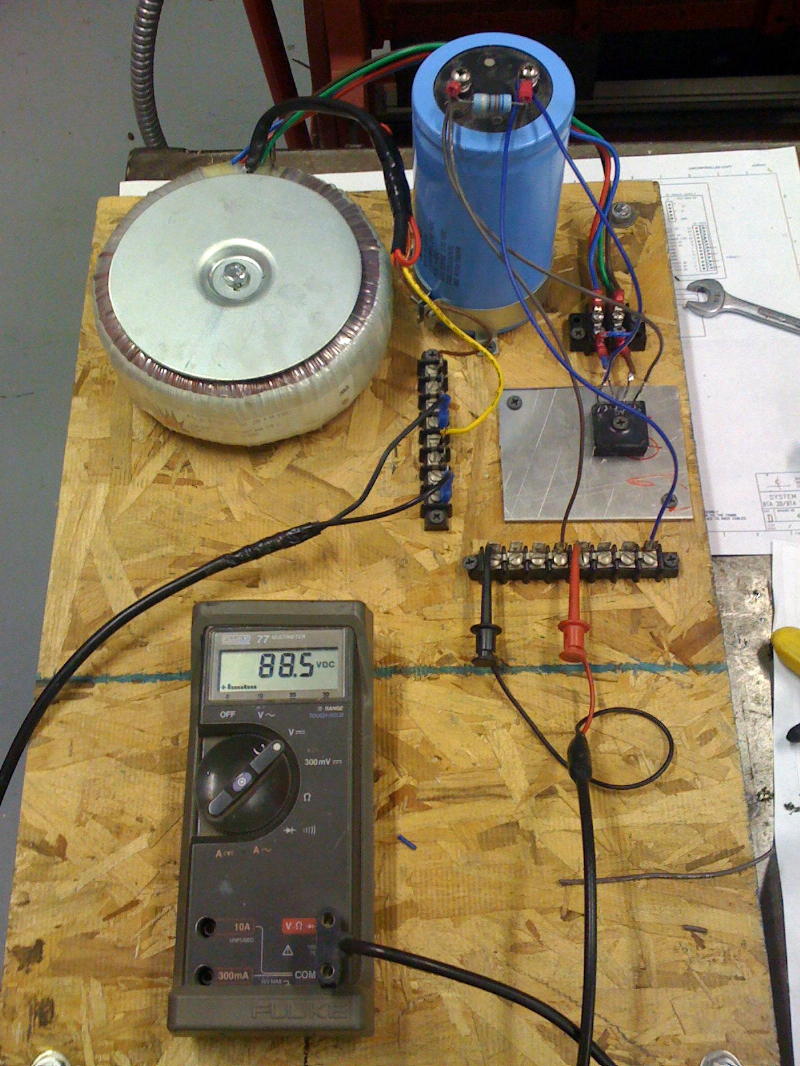

« on: December 08, 2009, 10:28:30 AM »I've also verified the supply voltage is holding well, never dropping more than about 1.5V from its nominal value.

If all 3 axis have a fast excelleration time, the power supply could be the issue. Did you use a scope to see the supply voltage or DVM? A DVM will filter out the surge/voltage drop. You might try a second supply just on the Z.

JH