21

Show"N"Tell ( Your Machines) / Re: My CNC pressbrake build

« on: December 30, 2009, 10:30:08 PM »

Finished drilling all the holes in the side plates.

Finished tapping the last hole in the upper beam.

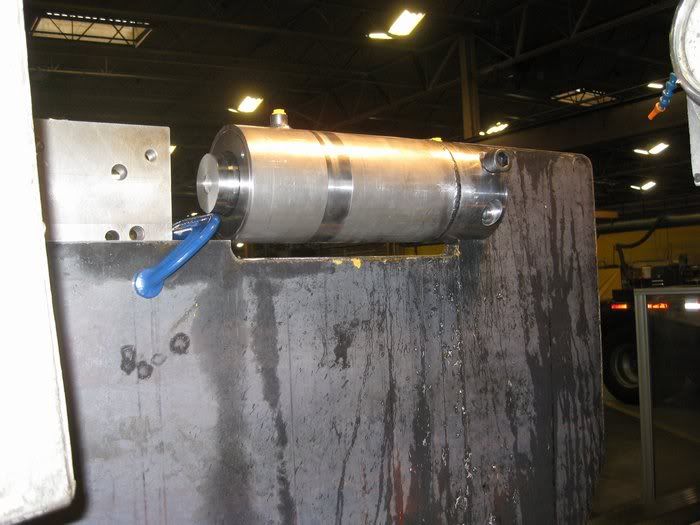

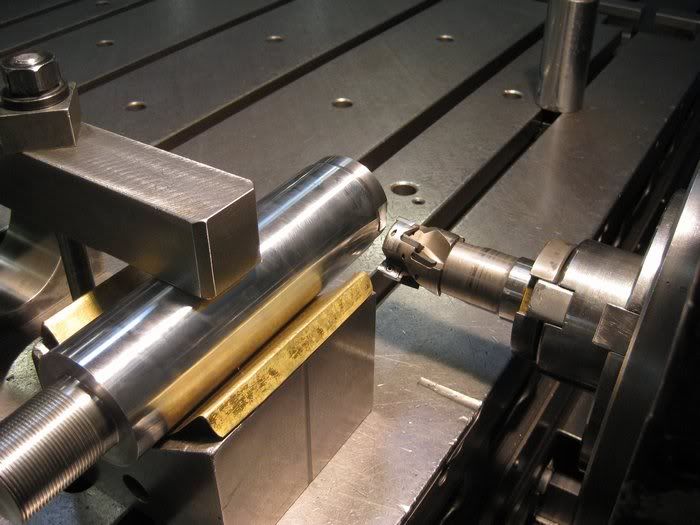

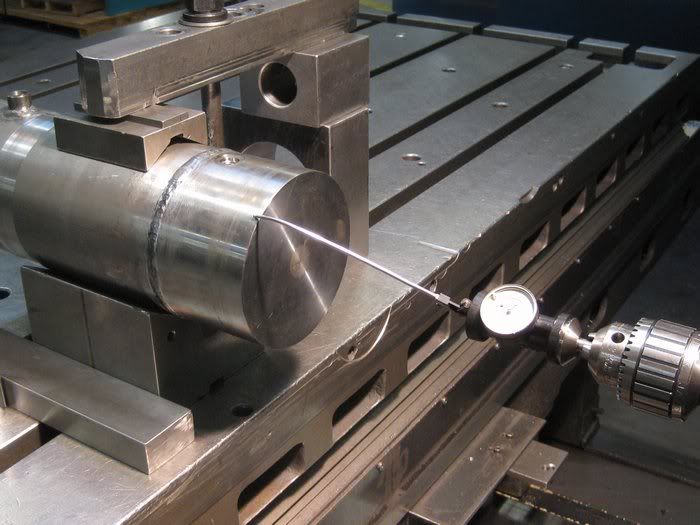

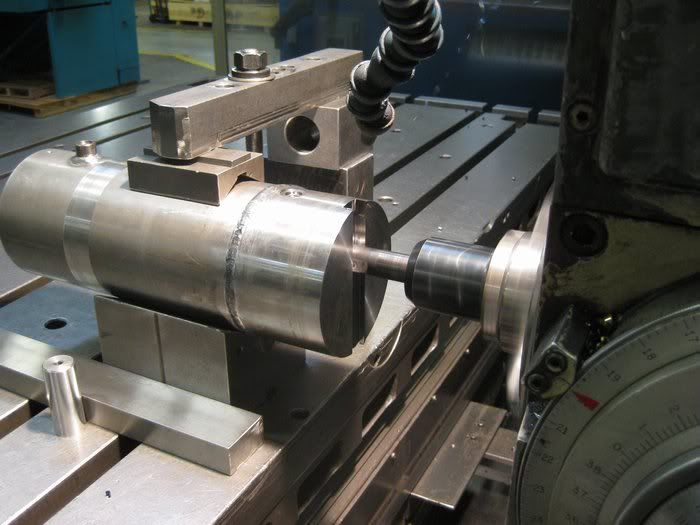

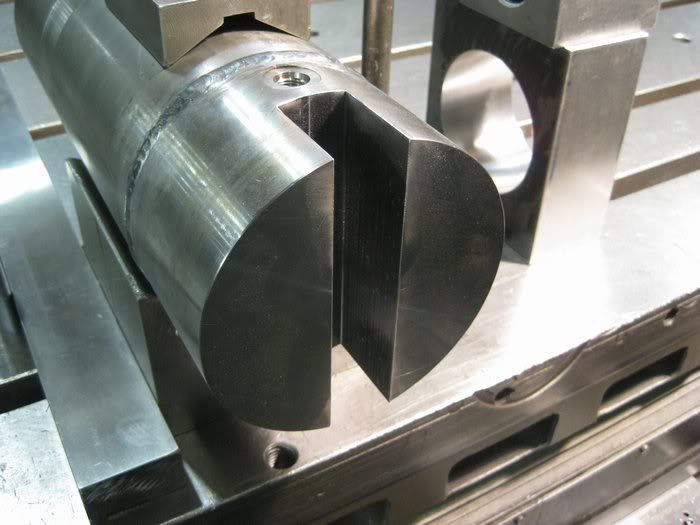

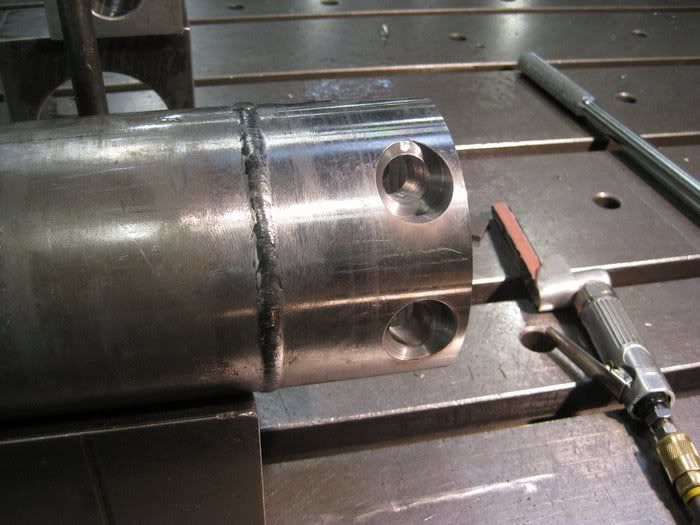

Turned some 4340 spuds to mount the cylinders to the beam.

Finished tapping the last hole in the upper beam.

Turned some 4340 spuds to mount the cylinders to the beam.

Very interesting project. What gauge metal will you be able to bend at 48 inches long? What radius will the bend be?

Very interesting project. What gauge metal will you be able to bend at 48 inches long? What radius will the bend be?