31

General Mach Discussion / Rotary table dividing calculator

« on: January 28, 2012, 06:49:41 PM »

Hi All

I guess this is decidedly non CNC related however it may come in handy on your manual mill.

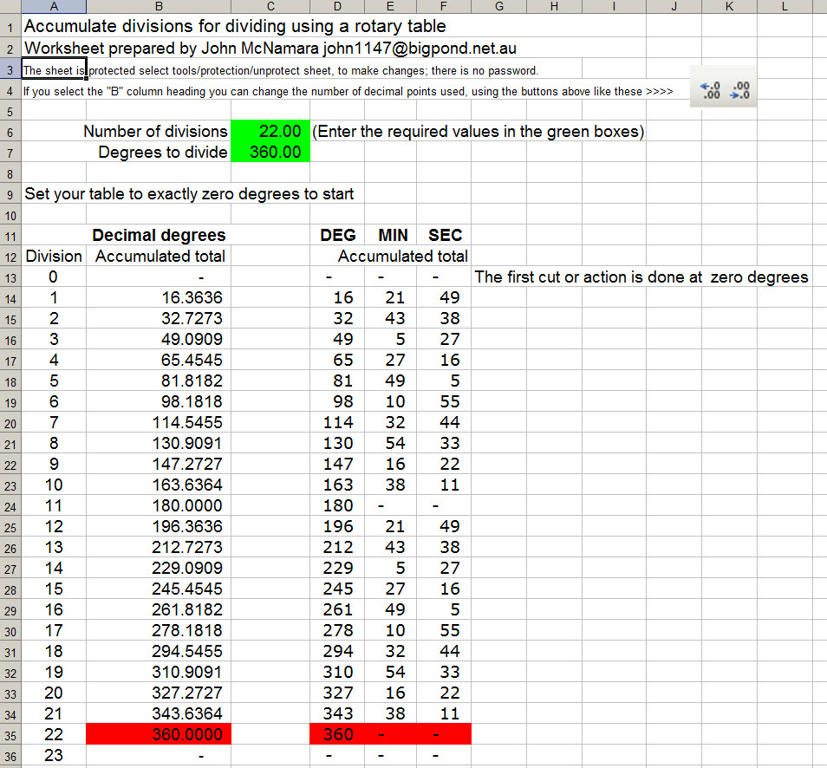

It is written in Excel (no macros) you can change it as you wish.

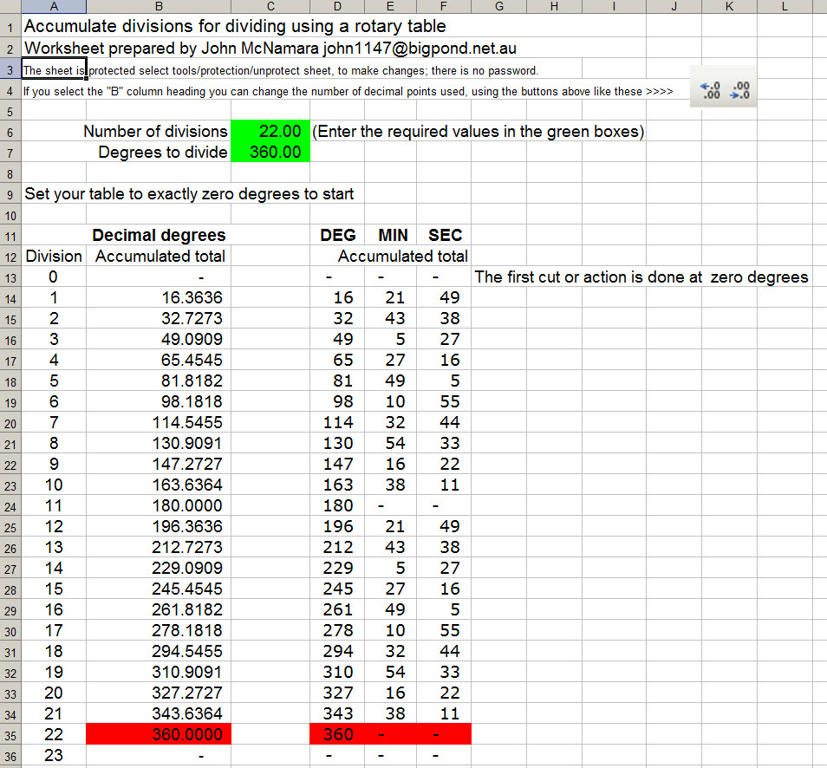

Enter the number of divisions and it will display all the decimal angles together with the same angle in DEG MIN SEC.

http://www.mediafire.com/file/yxheh2nvg2h3q7j/Dividing Calc 1.zip

Cheers

John

I guess this is decidedly non CNC related however it may come in handy on your manual mill.

It is written in Excel (no macros) you can change it as you wish.

Enter the number of divisions and it will display all the decimal angles together with the same angle in DEG MIN SEC.

http://www.mediafire.com/file/yxheh2nvg2h3q7j/Dividing Calc 1.zip

Cheers

John