861

Show"N"Tell ( Your Machines) / Re: Success! Mini Machining Center under Mach3 control - Video link

« on: April 09, 2010, 05:14:29 PM »

Hood, every time you speak, I realize how much I have to learn

I am aware of differential signaling being used for encoders (I use that myself), but are you saying that your servo drives also use differential step and direction signals? Does smoothstepper support differential step and dir signals?

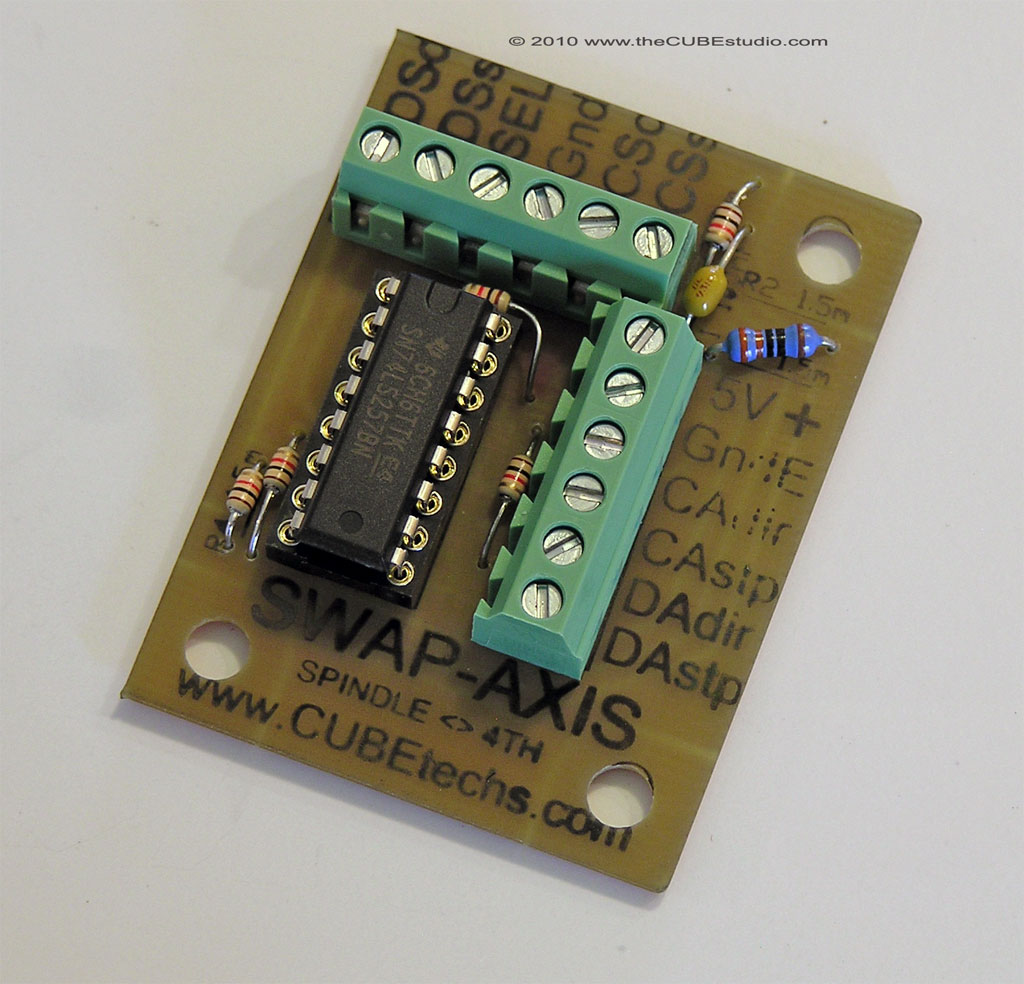

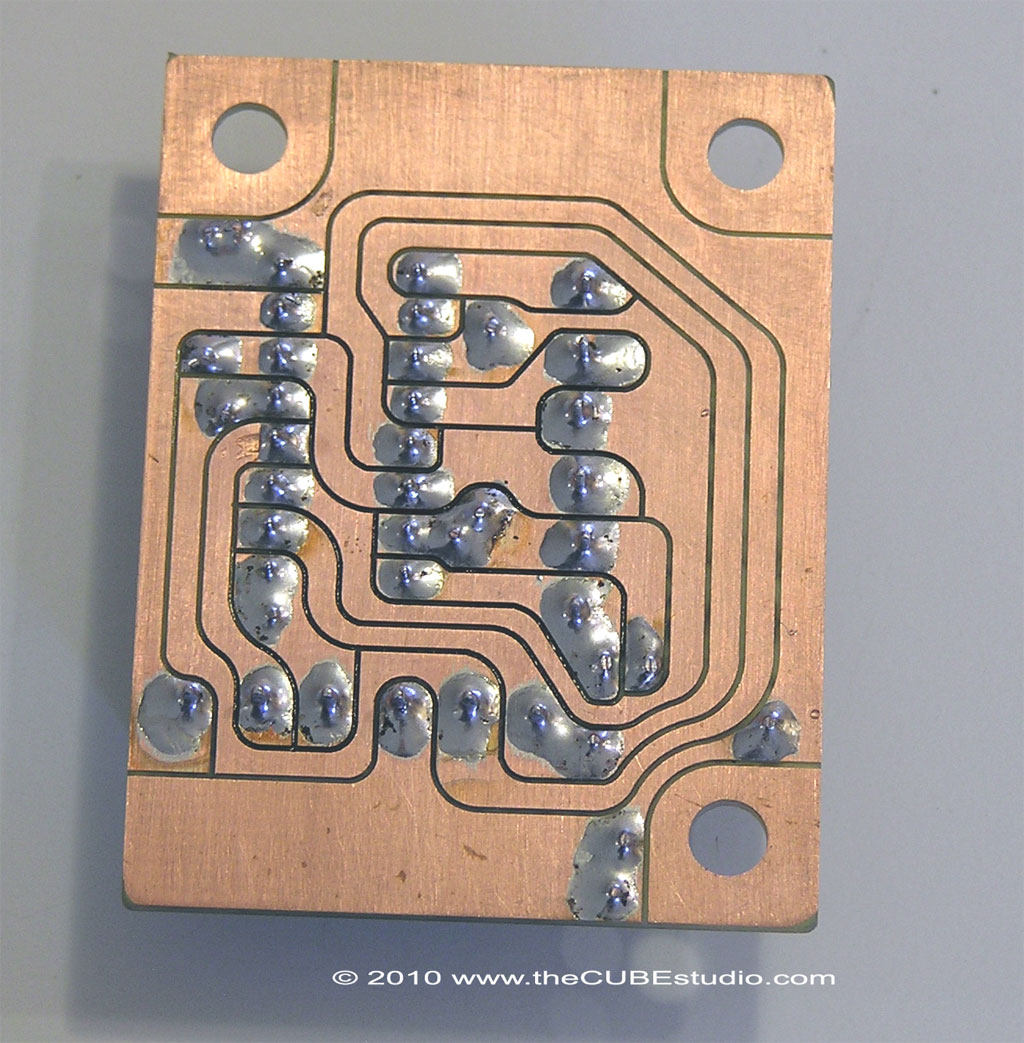

My board does not really 'accept' anything, it is just a signal switcher. It would not have enough lines for differntial signals, but I suppose you could use two of them. I don't think I would be inclined to pursue that unless your setup is common. I have not heard of using differential signals for step and dir. What would be the purpose except to mount the drives far away from the BOB?

I am aware of differential signaling being used for encoders (I use that myself), but are you saying that your servo drives also use differential step and direction signals? Does smoothstepper support differential step and dir signals?

My board does not really 'accept' anything, it is just a signal switcher. It would not have enough lines for differntial signals, but I suppose you could use two of them. I don't think I would be inclined to pursue that unless your setup is common. I have not heard of using differential signals for step and dir. What would be the purpose except to mount the drives far away from the BOB?