I think you use servo motor for Spindle.

Constantly moving, does not hurt to Servo motor?

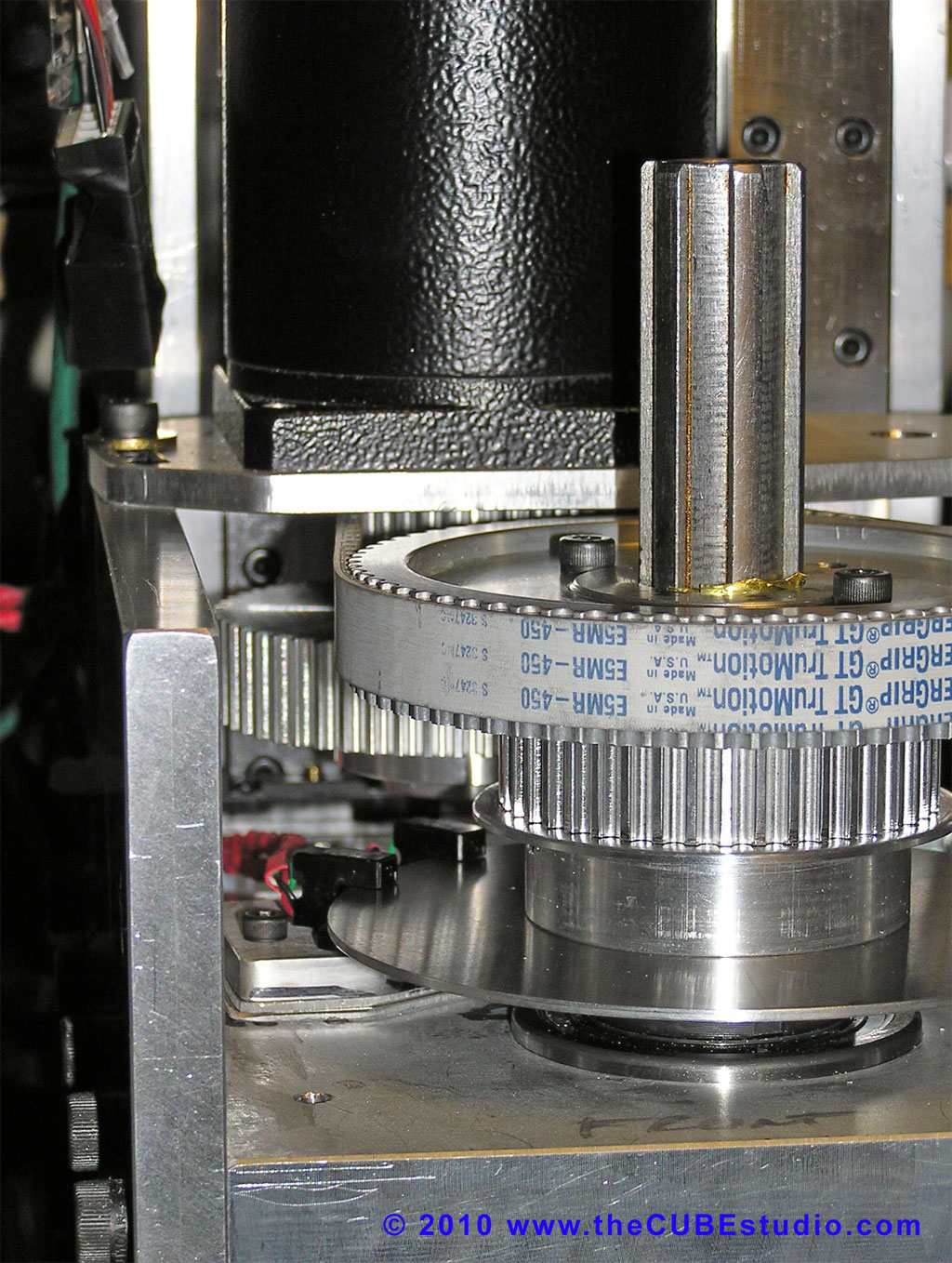

Servo motors do have a duty cycle and are expected to have 'rest' time and therefor have no provision for cooling. Running constantly might cause heat build up in the motor. The motor is rated 6,000 RPM and I have had no problems thus far running continuously at about 4,000 (a guess) with the mill on 'low range' if you will. On high range, at 7,000 RPM, both the spindle and the motor get hot after a while. On my previous X2 mill I ran 7,500 RPM for long periods and had an aluminum finned block on the side of the head to draw off the head. The spindle motor of the X2 has active cooling and it got hot, but not overly so.

In my application I do not plan to run the spindle at high speeds for more than 10 minutes or so at a time, so it is not a priority to investigate that. If I do need to run at the MAX 8,500 design speed for extended periods, I would need to add cooling to both the motor and spindle lower bearing. The lower bearing is currently pressed into a 1" thick block of aluminum which dissipates the bearing heat quite well enough for what I am currently doing.

Active cooling would be relatively easy to add.

) have their windings in the casing of the motor which means they are very efficient at dissipating the heat.

) have their windings in the casing of the motor which means they are very efficient at dissipating the heat.