You were talking about the finish on the disc springs, have you had them plated or is that the way you got them? The only ones I have ever seen have no plating at all and are black (maybe some sort of passivation?)

Black Oxide, most likely. By 'finish' I was referring to the smoothness. These springs came from McMaster-Carr. Some are very nice and cleanly punched and some have ragged edges or raised ridges at the OD from the punch die. On a brand name American made part, these imperfections would have been cleaned off, but with No-Name suppliers like McMaster, you don't know where most items are coming from . . although you can easily guess.

Raised ridges from the punch operation were left on the edges of the springs. These uneven raised edges, when facing each other in the stack, refused to stay aligned. The ridges would slip off each other driving the spring sideways with a very great force. The only solution was to remove this ridge and radius the ID slightly - by hand - on each of 60 springs. Now they are behaving, but that is WAY too much time to put into that component. For anyone contemplating a build like this, I would recommend buying the springs from the manuf, or at least know the brand name of the springs. However, reality check; I found springs that were nearly $4 EACH. That makes a US$240 stack. The stack I used was a little over $40 and the coil spring was a bit over $50. Functionally, the springs are fine and in any un-stacked application, the ridge would be insignificant, but for stacking, the quality of the finish must be very good or the springs will splay out.

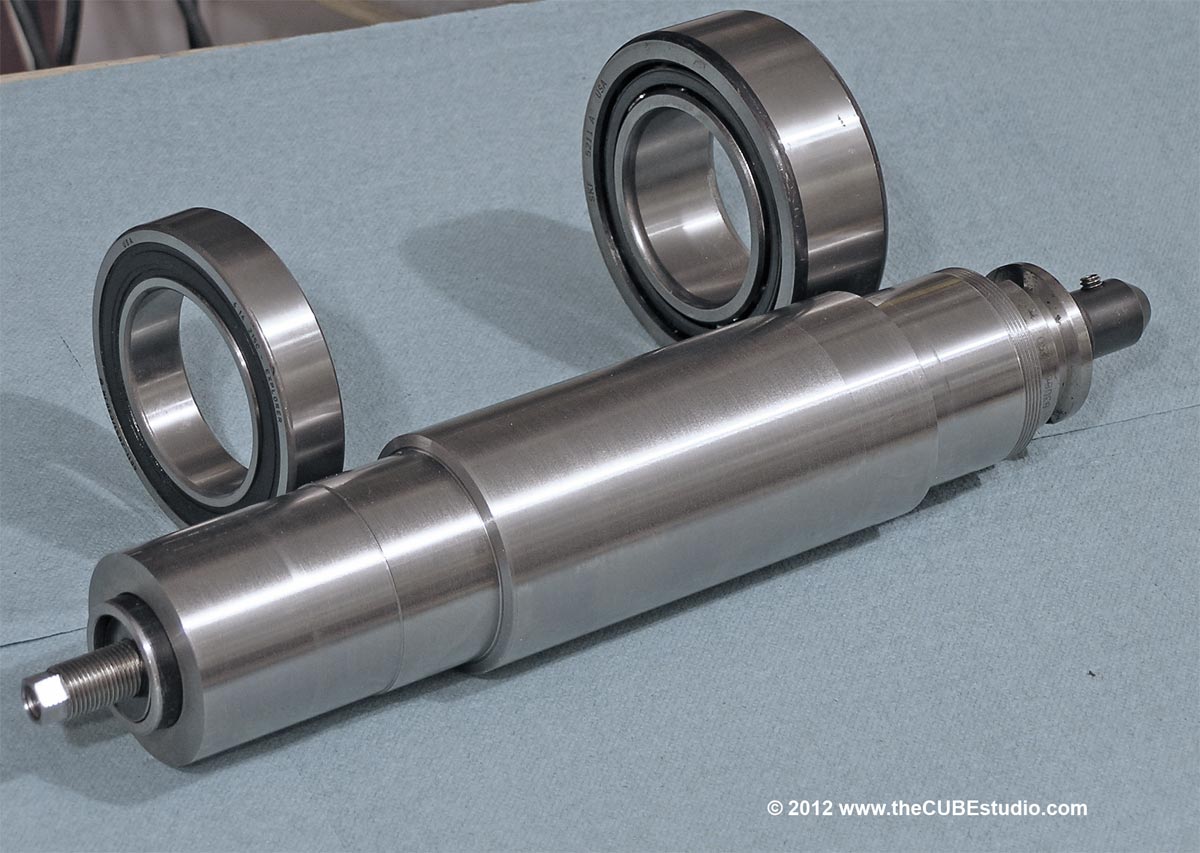

The way the cylinder and springs are designed on the Beaver mill is quite nice I think, spindle, drawbar and cylinder are all in one unit thus no pressure on bearings at all as far as I can see.

Hood

My R8 power drawbar did not put pressure on the bearings. But those are much smaller bearings. I just went thru the exercise of calculating the leadscrew force and the 400 watt motor faults at about 650lbs and the 750watt motor would push the head with about 1,250lbs. The drawbar is supposed to be run at about 600lbs, but even running it at 1,000 lbs, the release force is not much more than the spindle would see from the axis drive, albeit a lot more frequently. This is all academic really, because the bottom line is that the release is about 1,400 lbs and the bearing is rated over 10,000 lbs, so there is no concern over hurting the bearing.

The R8 drawbar was a different story with a much higher release force and a much smaller bearing. Actually, one can only imagine the actual force on a typical R8 spindle bearing that is generated by the shock force of hammering on the drawbar to release the collet.

Still, There is a large steel collar on the drive end of the spindle and it would be easy enough to just fork on that to eliminate release pressure on the bearings. Perhaps I will do that. This is a first prototype so it is 'legal' for me to change my mind 50 times as I go thru the build . .