41

Mach4 General Discussion / Re: Disable button border??

« on: July 01, 2015, 05:08:35 AM »Simpson posted some info on this a few months back.

Mach4 screen GRAPHICS -- makin' it Purdy - read all of that but nothing there unless Simpson found it and forgot to say

DazTheGas

I did not forget, I gave up in utter frustration at the developer's lack of interest in supporting people who are willing to spend their time working to provide MACH4 a more ergonomic and professional GUI . . . and sharing that with the community. Perhaps the most worrisome things about MACH4 is lack of support.

While I fully recognize that a user oriented screen editor must have certain restrictions to prevent novices from completely destroying the integrity of the system, refusal to add a feature like turning off button borders can only be pure stubbornness on the part of the MACH4 team.

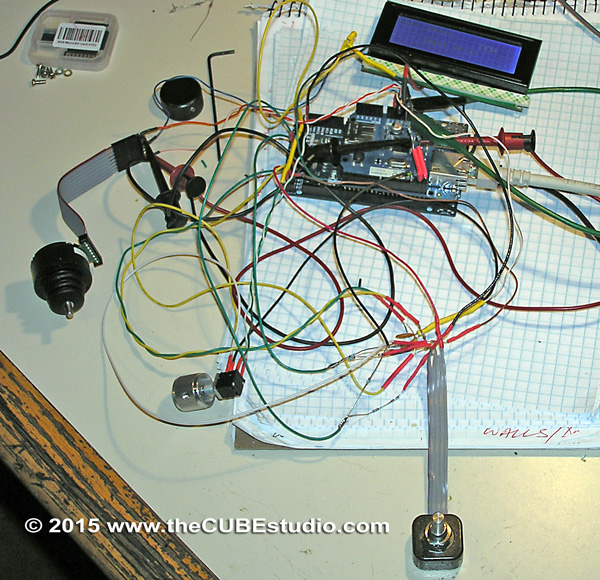

The reason I wanted the borders off the buttons was to have flexibility in adding realistic images of controls, but it turns out that the alpha channel is not working right on the MACH screens (initially I thought it was), so the usefulness of turning off the button borders will only result in advancing to the next roadblock, which again would require assistance from the developers . . so I just threw in the towel on using the MACH4 supplied utilities and relying on the MACH4 team to support the effort.

Having said that, it turns out to be an ill wind, because in researching alternatives, I found the 'real' toolbox full of tools in the LUA world. There are several very powerful graphics extensions in addition to wx and pretty much anything I can dream up is doable, but the methods are too advanced (in my opinion) to be sharable on a hobby forum. However, progress did not cease with the last post in that thread you mentioned, I simply stopped participating because the MACH4 tools are not being used.

You have already discovered the method, you just need the tools. Start with source forge and other repositories where you will find and recognize the example code that has been posted in this forum with two lines changed and the author credit removed. Move on to general google searches which will turn up a whole world of stuff. Pick out what suits you and dig in. You don't need to be held hostage by the MACH4 team.

Yes, I do have a bit of an attitude about this topic. I do not like having my time wasted on futile efforts.