Every time I have seen yet another 'power drawbar' thread, it has been here in the general section, so I'm starting here. If it needs to be moved, so be it.

I've been talking about this for a long time but there are a number of pices to the puzzle that have to come together and finally they are all in the sand box so its time to play.

Requisites were BT30, power drawbar (pneumatic only), Servo driven spindle, access to certain ATC parts. Ths big holdup was the Servo driven spindle, but I finally have that now. The new servo spindle drive is demonstrated in this 'intro to parametrics' video:

http://www.youtube.com/watch?v=Cu61oBY5-rwI have had the pneumatic cylinder and some other stuff for quite a while from when I was contemplating doing an R8 power draw bar. I abandoned that idea after a lot of research. I recently found a source for the 'fingers' that go on an ATC and hold the BT30 adapters.

A stumbling block was the $500 stud gripper for the BT30. There are two types of gripper that I know of; finger type and ball type. Either needs to be hardened and properly tempered to perform safely. I know how to do that, but I no longer had a furnace (sold with the prototyping shop many moons ago). So I have aquirde a furnace. I still have to install the new automated controls, but the 50A 220V wiring is completed.

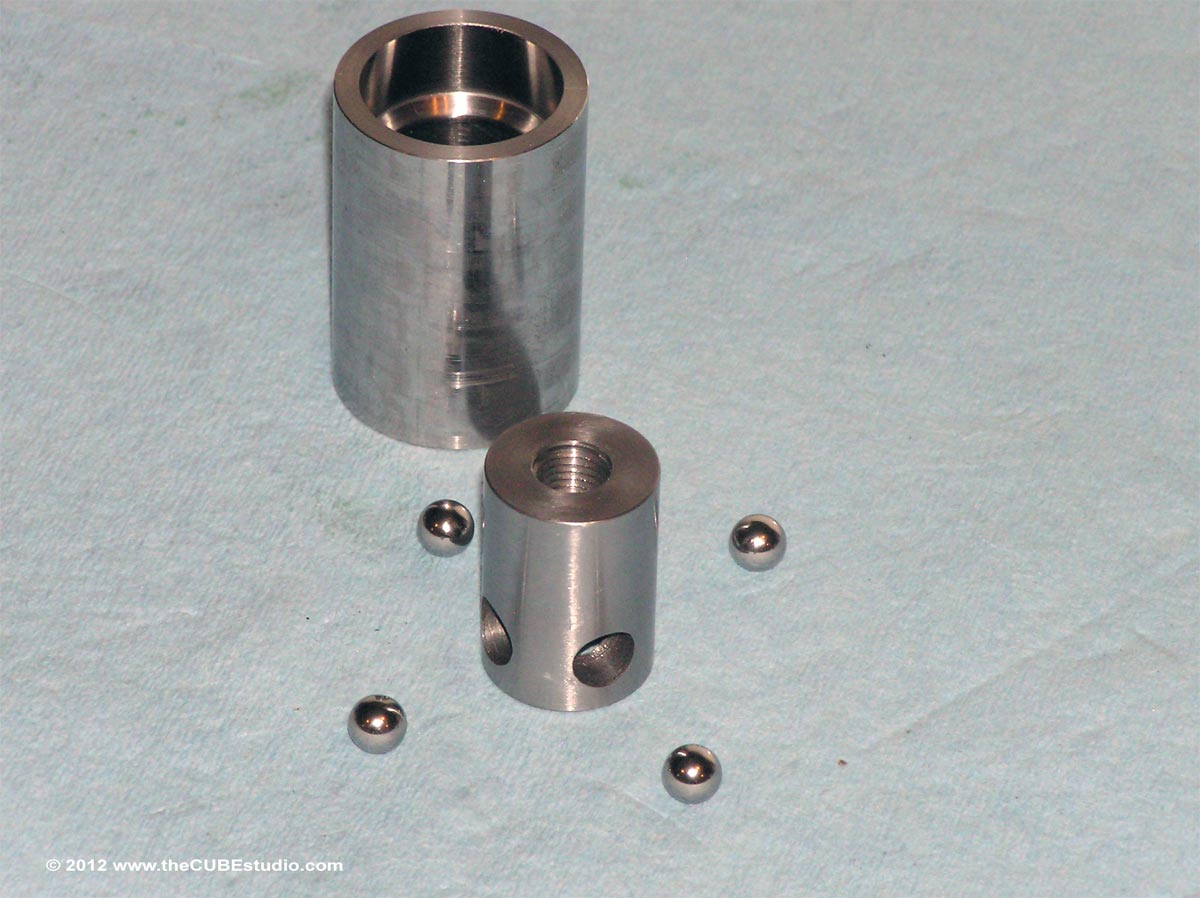

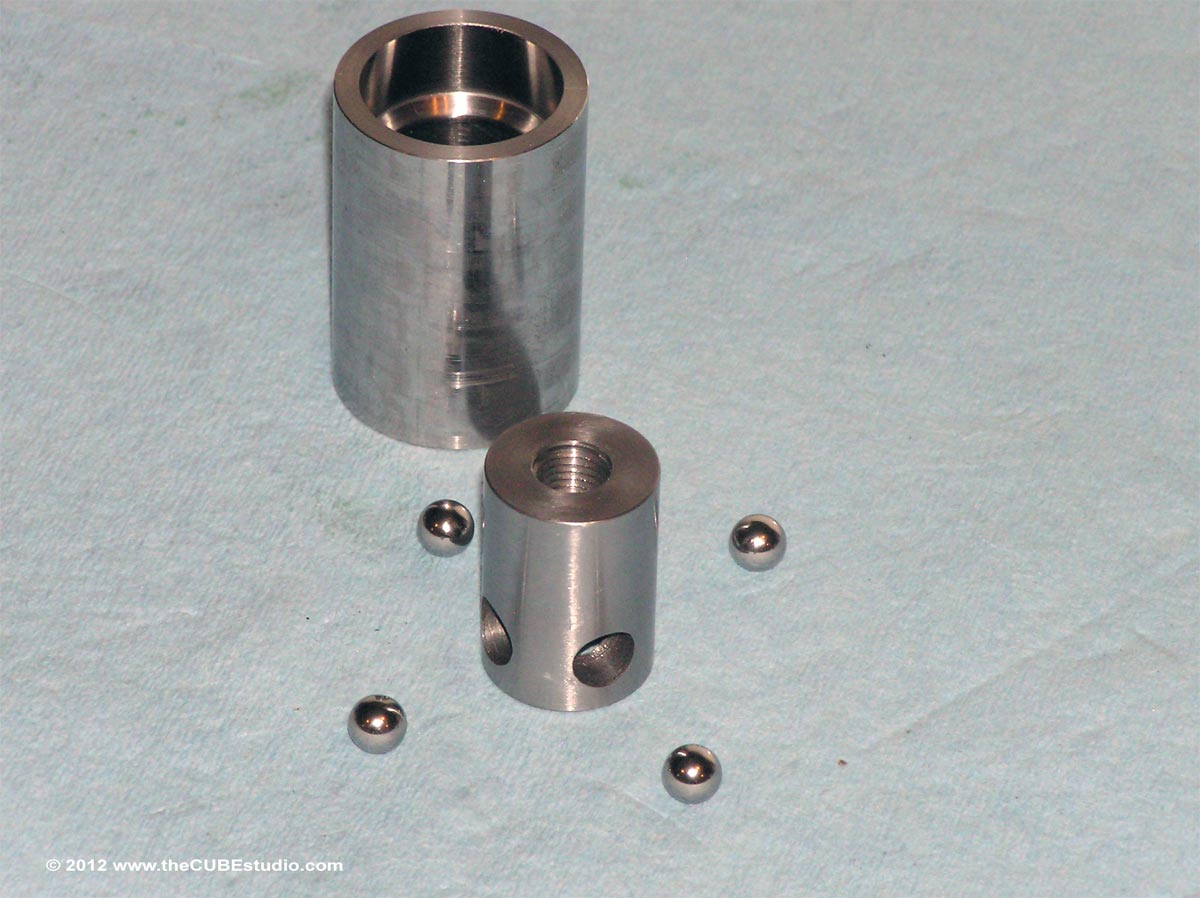

Meanwhile, I havecompleted the first amd most essential component, the above mentioned stud gripper. I went with the ball type. It works perfectly so all I need to do is turn doen the sleeve and harden the components. I have successfully completed my first scratch built spindle for my 4th axis, so I will use the same techniwues and new tools to make the mill spindle. Compared to making the stud gripper, everything alse should be fairly simple.

The center piece (hold the balls) is S7 tool steel while the 'sleeve' is A2. The sleeve OD is 'mill finish' as it has not been machined yet.

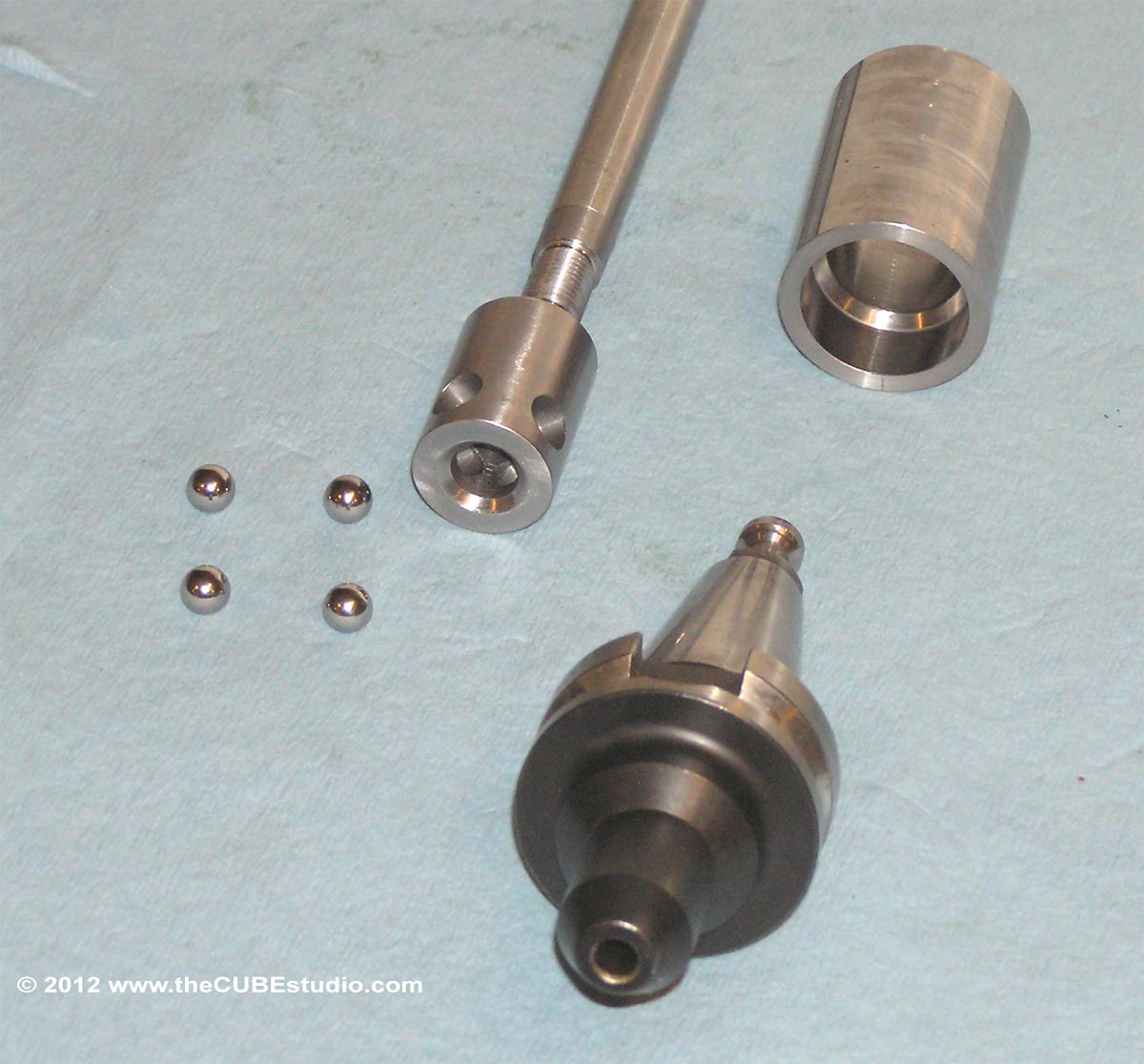

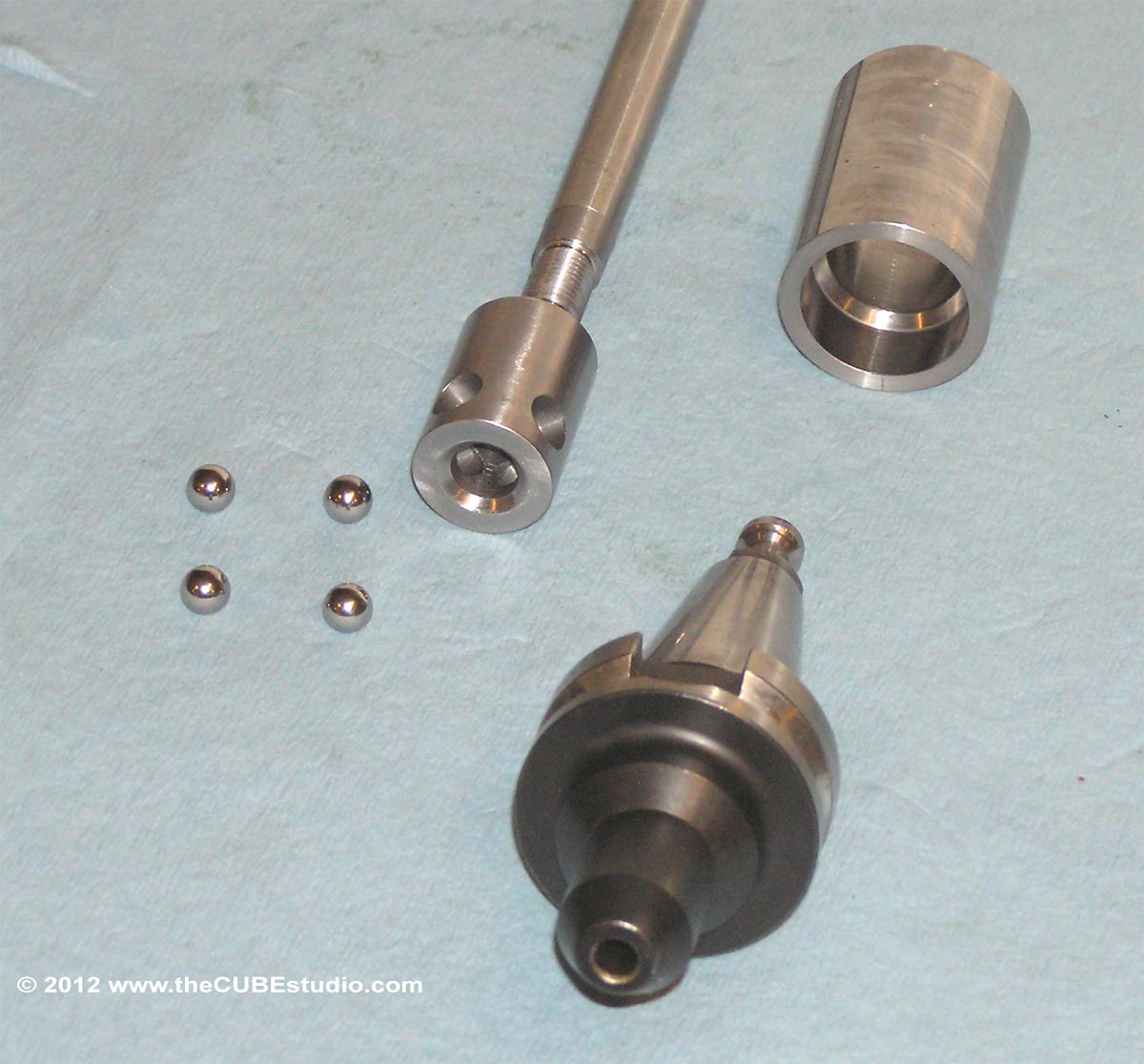

THe next two photos show the gripped in open and closed positions. I have colored the bals red becuase otherwise it was very difficult to see what was actually happening. This was the first round prototype and it works perfectly

so these actual parts will be hardened and used in the spindle.

so these actual parts will be hardened and used in the spindle.

so these actual parts will be hardened and used in the spindle.