281

General Mach Discussion / How to handle servo faults

« on: September 22, 2013, 04:28:52 PM »

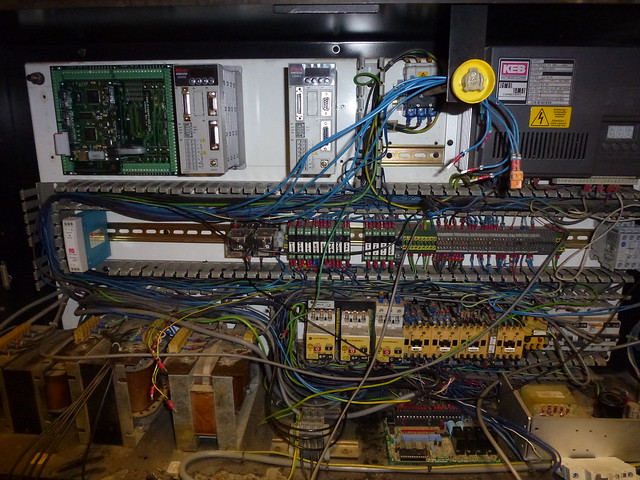

Originally I had planned to link the servo driver fault output into the e-stop circuit, so that if a driver faults out for any reason, the main power to all the drivers/spindle gets cut.

However, the issue with that is the drivers logic which is on a permanent 24V supply, would flag up a fault due to low voltage, meaning that to get them out of fault and power up the e-stop circuit, the drivers fault outputs would have to be bypassed, and a driver reset signal sent to all the drivers. Which although doable, would involve a few relays and a couple outputs.

To simplify things, I was thinking instead, just rely on the driver ready signal fed into the controller (I'm using a KFlop, so the controller itself can handle this and then report to Mach there's an issue) and halting motion if a drive enable signal fails.

I know it's not ideal, but then there are still limit switches to trigger an e-stop things if anything major goes wrong.

Does this sound feasible?

Also, I'd be interested to hear how others have servos wired up to deal with faults.

However, the issue with that is the drivers logic which is on a permanent 24V supply, would flag up a fault due to low voltage, meaning that to get them out of fault and power up the e-stop circuit, the drivers fault outputs would have to be bypassed, and a driver reset signal sent to all the drivers. Which although doable, would involve a few relays and a couple outputs.

To simplify things, I was thinking instead, just rely on the driver ready signal fed into the controller (I'm using a KFlop, so the controller itself can handle this and then report to Mach there's an issue) and halting motion if a drive enable signal fails.

I know it's not ideal, but then there are still limit switches to trigger an e-stop things if anything major goes wrong.

Does this sound feasible?

Also, I'd be interested to hear how others have servos wired up to deal with faults.