1

General Mach Discussion / MPG issues

« on: December 14, 2013, 06:14:57 PM »

Hopefully someone can help me. I purchased three MPG wheels off of ebay so that I can use my mill like a manual for small jobs and I thought it would be quite cool. I tried out and got strange results.

The MPG wheel is a 100 detent type that works from a 5v supply and on the back of the wheels are six terminals, + -, A B A- B-.

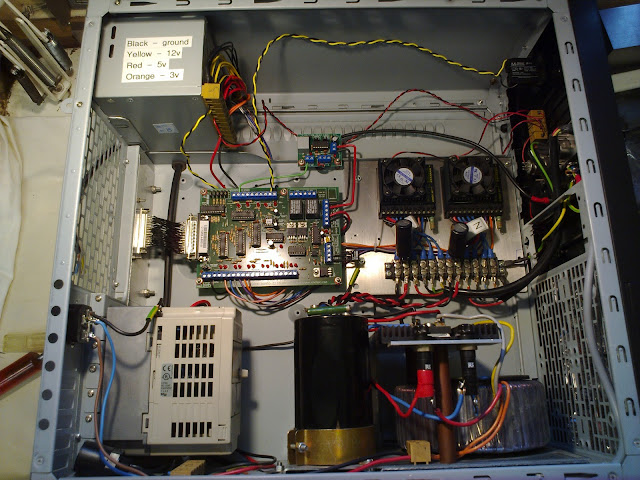

So, with a wheel connected its own 5v supply unit I wired up the A and B terminals to two spare input terminals on my C11G board which runs through a smooth stepper. The input indicator led's flash one after the other depending on the direction so I took that as a good sign. I setup the ports and pins as per normal and ran through the MPG config and got 4 pulses per indent, clicked save etc. I set the Jog settings to multi step and set the resolution to 1thou. Now when I turn the wheel in one direction it misses a few indents and doesnt turn the required amount, when I turn the other way it hardly moves at all, missing entire turns and then twitching.

It does seem to get a signal to mach 3 as it will move the motors but its extremely erratic and not really useable. So, im assuming that it is a software problem. I tried running this through my direct input board to the smooth stepper with exactly the same result.

Can anyone with a similar unit let me know what their settings are that may affect the operation of the wheels, Mach3 runs great in every other respect. In the ports and pins settings it says 4 yet this can be changed and doesnt seem to relate to the MPG config. How hard can this be....

The MPG wheel is a 100 detent type that works from a 5v supply and on the back of the wheels are six terminals, + -, A B A- B-.

So, with a wheel connected its own 5v supply unit I wired up the A and B terminals to two spare input terminals on my C11G board which runs through a smooth stepper. The input indicator led's flash one after the other depending on the direction so I took that as a good sign. I setup the ports and pins as per normal and ran through the MPG config and got 4 pulses per indent, clicked save etc. I set the Jog settings to multi step and set the resolution to 1thou. Now when I turn the wheel in one direction it misses a few indents and doesnt turn the required amount, when I turn the other way it hardly moves at all, missing entire turns and then twitching.

It does seem to get a signal to mach 3 as it will move the motors but its extremely erratic and not really useable. So, im assuming that it is a software problem. I tried running this through my direct input board to the smooth stepper with exactly the same result.

Can anyone with a similar unit let me know what their settings are that may affect the operation of the wheels, Mach3 runs great in every other respect. In the ports and pins settings it says 4 yet this can be changed and doesnt seem to relate to the MPG config. How hard can this be....