1

General Mach Discussion / Re: Mach3 logic help

« on: September 02, 2016, 06:43:30 PM »

Somehow the settings were dafuqed, and I was left miserable.

I had no chance to play with it today, but I will set it up as high as I can, and give an update here.

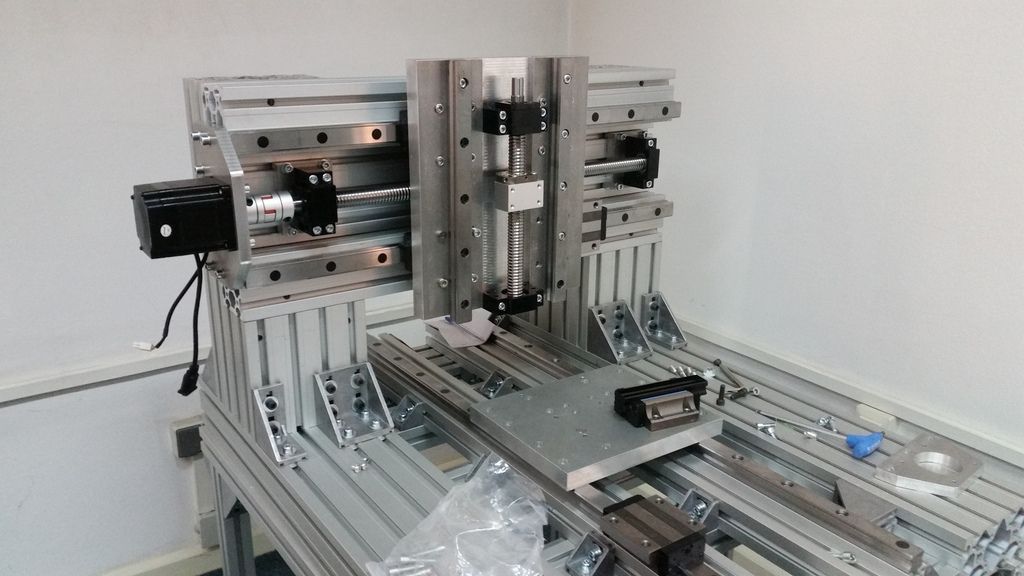

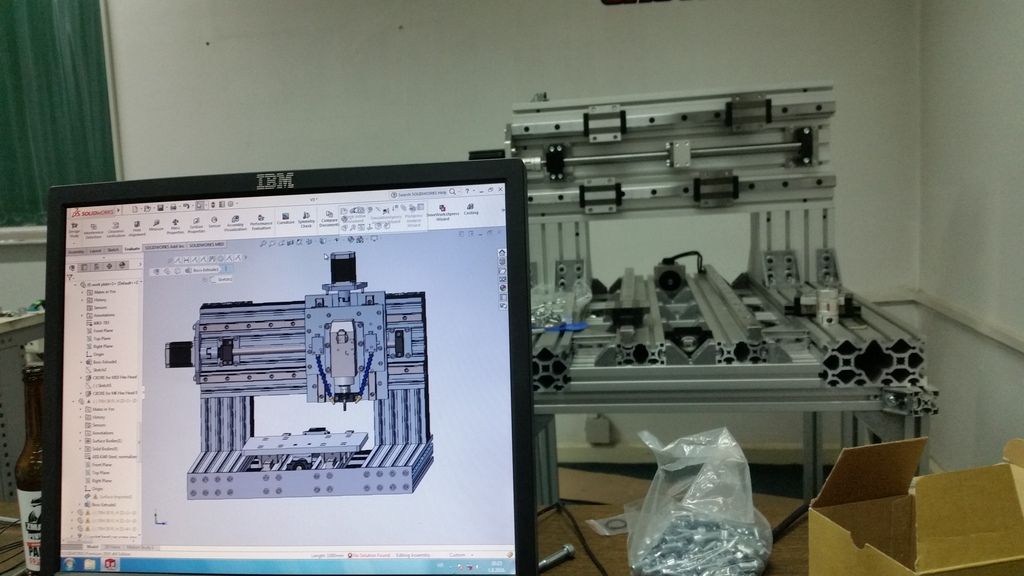

Making my move to make a heavy duty table to sit on, and flood it with epoxy, for vibration reduction.

Also, will post a render of the whole machine.

Thank you for such a detailed explanation, and I will try to give it a few tests with off settings.

I had no chance to play with it today, but I will set it up as high as I can, and give an update here.

Making my move to make a heavy duty table to sit on, and flood it with epoxy, for vibration reduction.

Also, will post a render of the whole machine.

Thank you for such a detailed explanation, and I will try to give it a few tests with off settings.

I am on to something now, as I have been playing with setups today, and here are my current machine setup.

Velocity 6000 mm/s

Accleration 1000/s/s (was set to 300 mm/s/s)

Throughout the thread you've said your accel was 2000mm/s/s.

If you actually have been using 300mm/s/s then that explains everything you've been seeing. 300mm/s/s is hopelessly low for CV to produce the accuracy you're trying to achieve.

When using CV mode, the accuracy of the actual path, i.e. how close it is to the programmed path, is directly proportional to acceleration. This I'm afraid is true of every machine and every controller on the planet - blame it on the laws of physics.Acc: 2000mm/s/s goes up to 4000 mm/s/s without problems, but that is insane acceleration.

What's insane about it? 4000mm/s/s is not particularly high for a truly rigid machine. if your machine is capable of 4000mm/s/s then that is what you should be using. The ONLY reason you would turn DOWN accel. is when the jerk your drive system is capable of creating exceeds the rigitity of your machine.

A word about Mach3's CV settings like dist. tolerance etc.

ALL CV settings are there to try to help when a machine's acceleration is not good enough for the job expected of it. i.e. they ALL stop CV from working to its fullest extent one way or another i.e. they all take CV closer and closer towards exact stop. On a machine with accel. good enough for the job expected of it - they should ALL be completely OFF.

Finally a note for Dave. A Lookahead of 1000 is at best nearly always pointless and at worst counter productive. I don't really care about the hair-pin at john o'groats before I've left the car park at land's end. Well unless I'm travelling at the speed of light and my brakes are really crap - then I might.