I am interested how you got the Fanuc VFD to work?

Dan

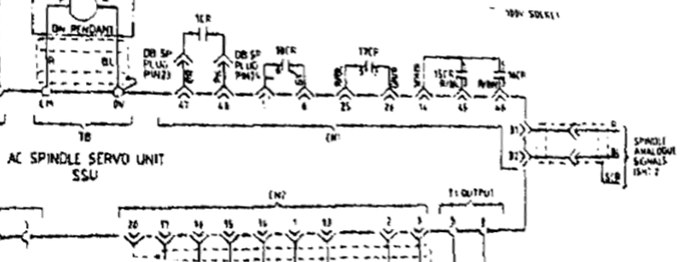

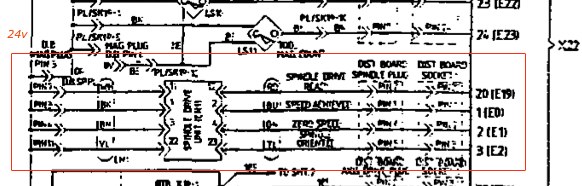

Biggest issue was that I didn't have info about the connector. Which wire did what. A huge puzzle.

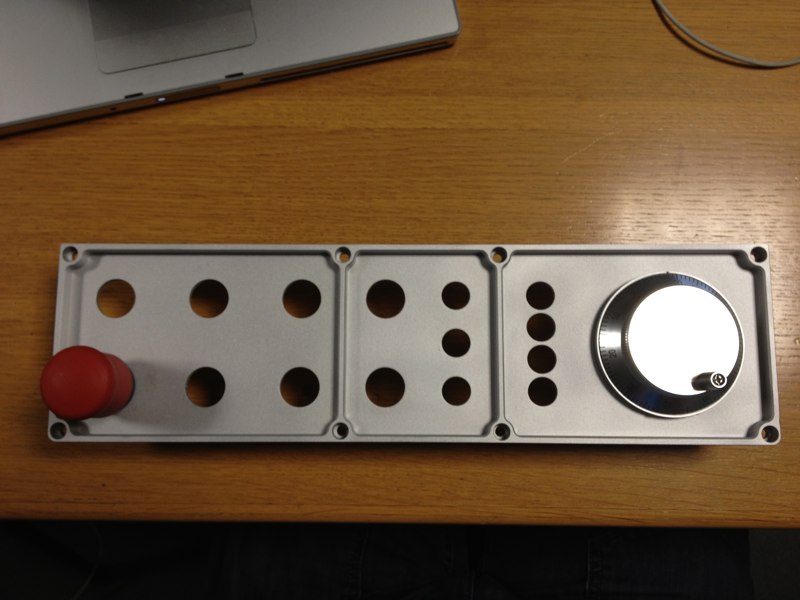

The Fanuc uses 0-10v speed, CW and CCW direction, Alarm, Drive ready, Speed achieved and zero speed, Orient and orient achieved and E-stop.

"Eventually I decided to rebuild to Mach3. A bit of a gamble. Not much experience with Mach nor G-code but I thought it was nice challenge."

Wow, if your doing this level of work, and not much experience, then I will LOVE to see your work, when you become experienced!!! Your work, is EXCELLENT, Great Job!!

I have never used the CSMIO/IP-x, series of controllers....... but the way Hood is going on and on about them, maybe I should try one!!

Again, really nice work!!

Scott

Thank you Sir!

I only worked with Heidenhain dialog so far. Have been working with a 410 for a couple of years. The 308's 2500 is a bit older dialog and missing some cycles compared to the 410. Both can do G-code (ISO) but I never bothered. G-code is new for me. I think it has been 6-7 month since I started using, or testing better said, Mach3 and most has been configuring Mach itself. I have been working with computers all my live and learned an older programming language some 30 years ago so I'm not totally unfamiliar with the matter but a lot is forgotten over the years.. From the electronics side I do have some recent experience wiring cars, retrofitting standalone engine management systems in this case, and in the past I did maintenance on printing presses. So also here not totally unfamiliar. Never rebuild a wiring cabinet to this extend though. I did have some help but wanted to do the actual wiring myself.

A small video clip of the first run.

<a href="http://www.youtube.com/v/omeSv9P2cy0" target="_blank" rel="noopener noreferrer" class="bbc_link bbc_flash_disabled new_win">http://www.youtube.com/v/omeSv9P2cy0</a>(There a loud air compressor running in the background)