1

General Mach Discussion / Re: parts are the wrong size

« on: March 17, 2013, 03:07:17 PM »

status update!

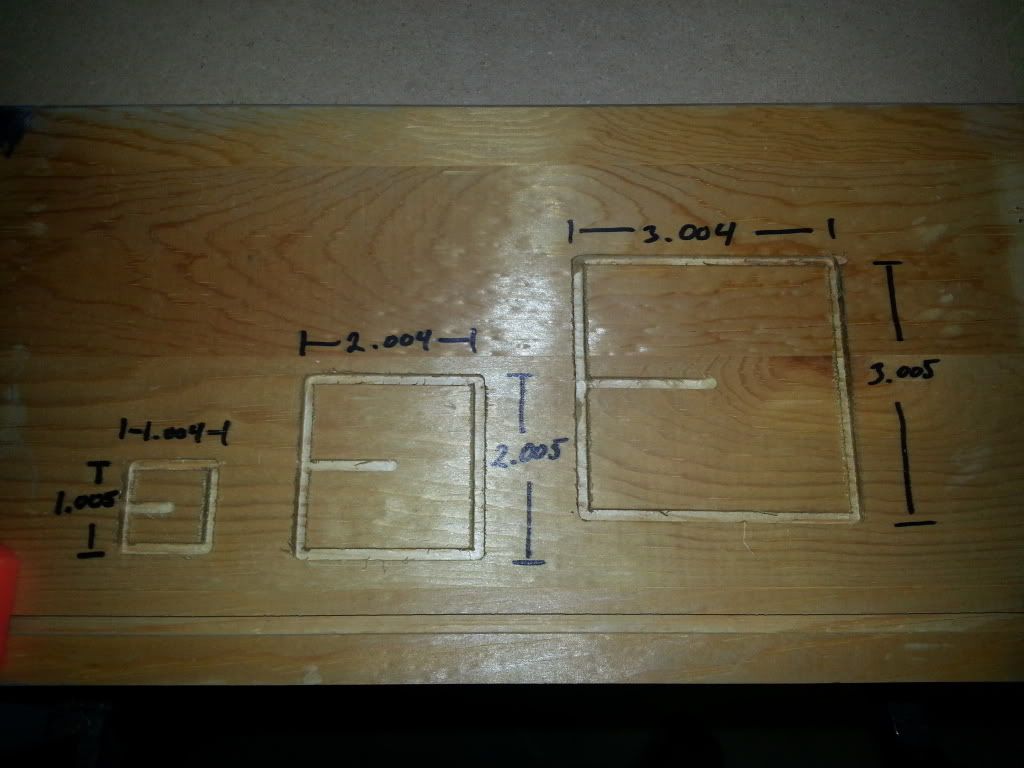

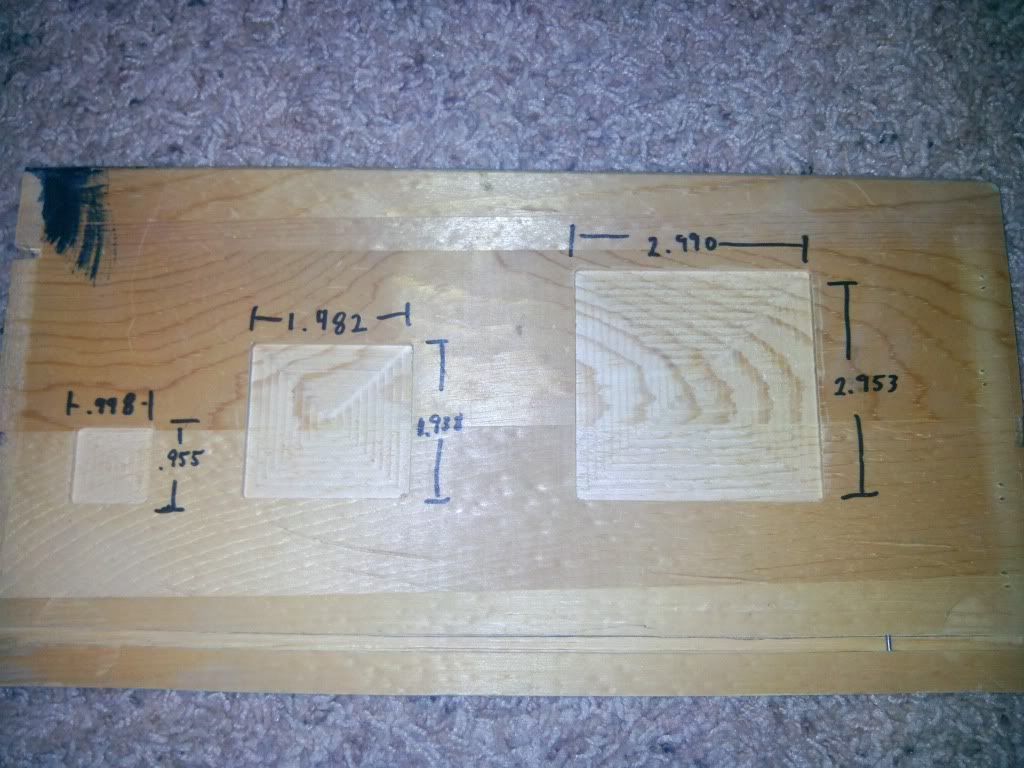

i have gotten it all sorted out. i finally had the time to sit down and properly calculate the steps per for the y axis. the reality of it is still off a small amount from the calculated, but i know have it very accurate and repeatable. there was also a small amount of backlash that i am now compensating for as well. between the 2 the machine is now right on the money. at least in the y axis.

now i need to fix the x axis. this was the better of the 2 but now that the y is so dialed in, x is now the problem child.

i already know the problem here as well. it is direct drive and can not make small enough steps for the accuracy i am trying to achieve. so gear reduction is in order.

Thanks again to everybody who helped along the way. much appreciated!

i have gotten it all sorted out. i finally had the time to sit down and properly calculate the steps per for the y axis. the reality of it is still off a small amount from the calculated, but i know have it very accurate and repeatable. there was also a small amount of backlash that i am now compensating for as well. between the 2 the machine is now right on the money. at least in the y axis.

now i need to fix the x axis. this was the better of the 2 but now that the y is so dialed in, x is now the problem child.

i already know the problem here as well. it is direct drive and can not make small enough steps for the accuracy i am trying to achieve. so gear reduction is in order.

Thanks again to everybody who helped along the way. much appreciated!