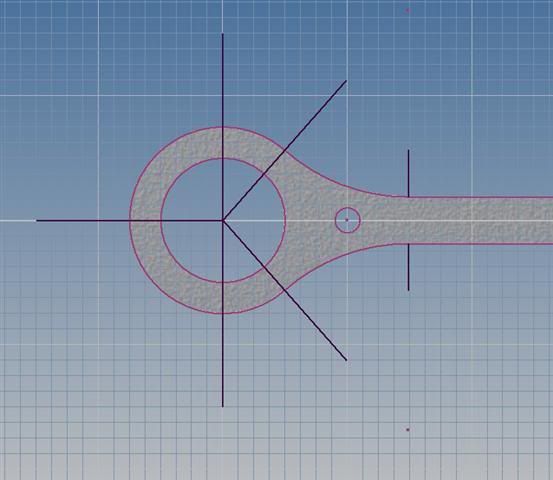

The outside arc radii are 0.75" and 0.375", and the inside radii (the fillets) are 1.5". I used a 1/2" endmill for roughing and a 1/4" stubby endmill with large shank for the finish pass. It's a LMS mini mill with the CNCFusion ballscrew package. These are some of the first parts coming off the machine, so I can't speak to whether this is something that just cropped up or not.

The length of the flats are .160" on the outside of the large diameter (0.75") and 0.120" on the outside of the smaller diameter. They're also not flat, now that I take a close look. They're definitely arcs in and of themselves.

If this were due to backlash, I would expect to see a seam any place an axis changes direction, but only there. In other words, I should see variation at these points, and these points alone:

Outside of the backlash, the axes are very consistent - example: I make a g0 move from x0 to x-3.7500, then from x-3.7500 to x-3.5000. I now zero the glass DRO, and I can make any move in the positive direction and be pretty much dead on (within a couple of ten thousandths, anyway).